March 2023

CAN COATINGS: UNLOCKING THE FUTURE OF SUSTAINABLE PACKAGING

A WHITE PAPER FROM SHERWIN-WILLIAMS

1. OVERVIEW

All businesses have a role to play in the transition to a more sustainable economy and way of life. At Sherwin-Williams Packaging Coatings (Sherwin-Williams), our contribution is met through a steadfast commitment to innovation, product excellence and sustainable technologies.

As governments around the world seek to achieve ambitious climate targets, it is paramount that industry drives this transition by mobilizing its innovative capabilities, deep technical expertise and insights into market dynamics to develop sustainable products and solutions that will help to preserve the environments and societies in which we live and support the wellbeing of current and future generations.

Although we may not always stop to think about the way we package and preserve our food, drinks and everyday household items, packaging plays an essential role in our daily lives. Packaging ensures that our food remains fresh for longer, reducing global food waste and supporting the transportation of goods around the world.

However, as recognized by the United Nations Environmental Programme, because of poor disposal and recycling practices, some types of packaging waste have become a pervasive global environmental challenge.1 A global issue that everyone — governments, organizations and individuals — must urgently address.

The ambitious goals enshrined in the European Green Deal and the Circular Economy Action Plan set the stage for a comprehensive review of the way in which we use, reuse and recycle packaging. The latest development in this mission to achieve a sustainable packaging supply chain in Europe is set out in the proposed Packaging and Packaging Waste Regulation (PPWR).

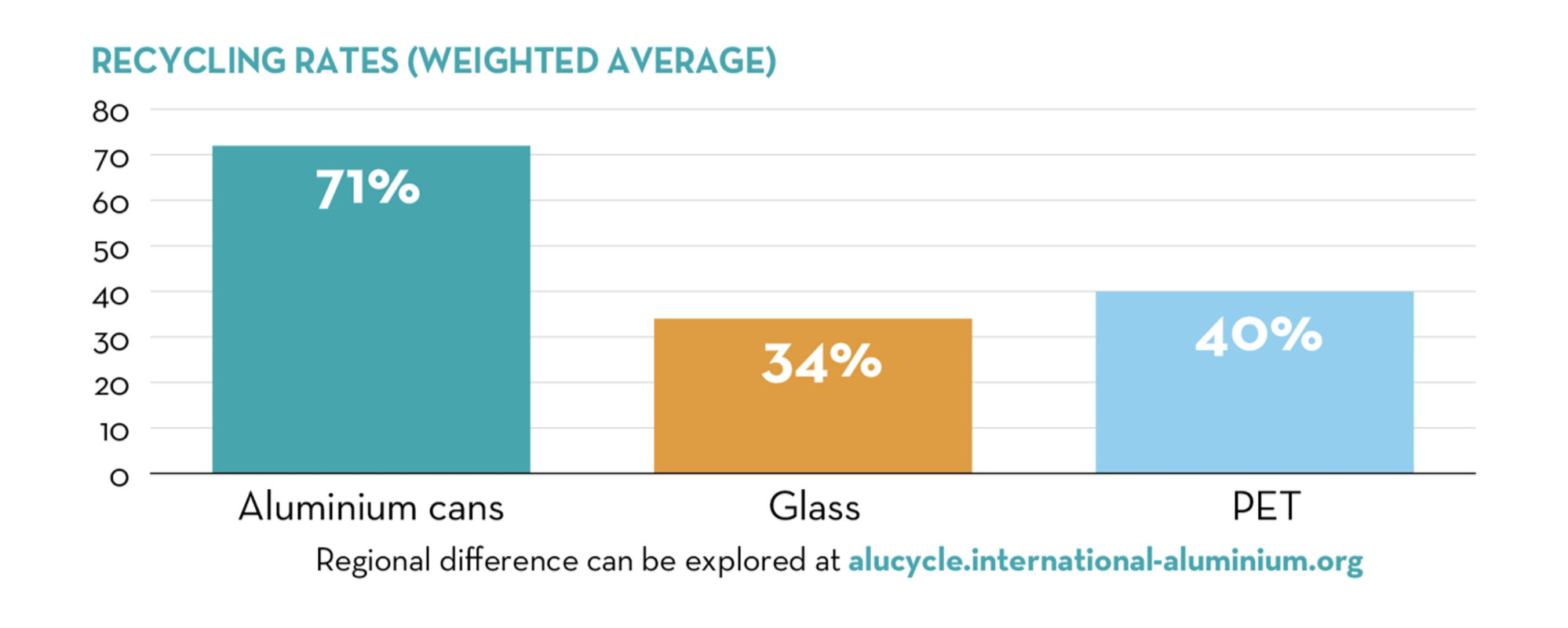

Among the diverse range of packaging types available, the metal can has stood the test of time, remaining an efficient and sustainable choice favored by the market. Metal packaging is an essential part of global supply chain that is relied upon to ensure access to affordable, safe and long-lasting food and beverages. It is estimated that Europeans use up to 50 billion cans every year for products like water, soft drinks, alcohol and beer.2 Aluminum cans can be recycled indefinitely, making them an optimal packaging solution. Over 70 percent of all aluminum cans are recycled globally, making them one of the most recycled packaging types on the planet.3 It is estimated that an average of 113,200 aluminum cans are recycled every minute.3

The sustainability benefits of the metal can would not be possible without the use of specialized can coating technologies. Metal cans are coated with a thin layer that protects the integrity of the cans, enabling them to hold the food or beverage. Without coatings, cans are susceptible to packed product spoilage and/or metal corrosion. Can coatings are generally formulated to ensure compatibility with hundreds of different product requirements and do not impact the ability of the can to be recycled.

Can coatings have evolved substantially over time, however, the purpose and importance of can coatings remain unchanged.4 While the metal package is a solution for achieving a sustainable packaging industry, goods cannot be packed successfully in metal without the use of can coatings. Therefore, for cans to work successfully as a sustainable solution, they depend on continued innovation by can coating manufacturers like Sherwin-Williams to develop can coating technologies that protect the quality and integrity of food and beverage products. These innovative can coatings ensure food safety, extend shelf life, and reduce food spoilage and waste.

As a leader in can coating solutions, Sherwin-Williams is driving innovation in can coatings to ensure we are supporting the ambitious packaging requirements of the future.

Over 70 percent of all aluminum cans are recycled globally.

2. FUTURE OF METAL PACKAGING IN EUROPE

Policymakers and regulators in the European Union (EU) are sending clear signals that industry must accelerate efforts towards a future without packaging waste. In late 2022, the European Commission presented its proposal for the PPWR, an ambitious piece of legislation that will significantly reduce packaging waste in Europe by 2040 by encouraging reuse and recycling. EU legislators are working to finalize the legislation by early 2024.

The PPWR will set recycling targets for EU countries for total packaging and across each packaging material, including metals used to produce cans. Under the Commission proposal, EU Member States would be required to reduce all packaging waste by 5 percent by 2030, 10 percent by 2035 and 15 percent by 2040. By 2030, countries in the EU would need to ensure that at least 60 percent of all aluminum packaging is recycled, and further ambitious targets are likely to be set for the following decades, culminating in the overall goal of a climate neutral European economy by 2050.

Fortunately, metal packaging is highly recyclable, acting as a successful case study for the packaging industry as it adapts to meet the targets set by the European Commission. According to Metal Packaging Europe, the overall recycling rate for aluminum cans in the EU reached a record of 76.1 percent in 2019, while steel cans reached an all-time high of 84 percent.5 Aluminum, which is the main metal used in beverage cans, is infinitely recyclable without loss to the properties that make it an attractive option for brands and retailers. Although recycling systems differ from country to country, the process for recycling aluminum cans is well established, and it is estimated that used cans can be transformed into new ones in just two months. For alternatives such as plastic and glass bottles, used materials lose key properties during processing and must often be downcycled, whereby the recycled material is of lower quality and is not as structurally strong as the original product.

The process for recycling aluminum is highly energy efficient, and aluminum cans outperform PET and glass in terms of energy usage (see Figure 1).6 The recycling of aluminum in packaging therefore results in a lower overall impact on the environment than other forms of packaging, helping companies meet the emissions reduction targets set out in the Paris Agreement.7 Recycling aluminum takes 95 percent less energy than producing it from its raw materials, offering an important motivation for brands, consumers, can makers and retailers to ensure that used packaging is recovered, particularly during a period of unprecedented energy costs in Europe.8

Sustainability and performance benefits are at the heart of the shift towards metal packaging for beverage producers, with brand owners choosing cans over alternatives in increasing numbers.

Metal packaging is highly recyclable, acting as a successful case study for the packaging industry as it adapts to meet the targets set by the European Commission.

3. ROLE OF CAN COATINGS IN ACHIEVING SUSTAINABLE PACKAGING

In the EU, nearly 57 million tons of food waste are generated annually, with an associated market value estimated at €130 billion ($141 billion).9 A recent report from Feedback EU found that the EU wastes more food than it imports, emphasizing the importance of sustainable solutions for food preservation, particularly at a time of high food prices and a cost-of-living crisis.10

According to research conducted by Can Manufacturers Institute, one of the main reasons for food waste is the inadequate preservation and storage of food.11 Canned goods provide safe, quality and nutritious food with a multiyear shelf life. Canned goods are made possible through can coatings, which provide a protective barrier between the product and the can. For consumers, can coatings enable safe storage for long periods after purchase, while for the producers, can coatings allow food to be exported all year round, using lightweight, affordable and sustainable packaging while preserving taste, texture and color.

The same properties make cans a preferred packaging solution in the beverage market. With 75 percent of new beverages now launched in cans, can coating technologies allow brands to reduce their reliance on plastic packaging and switch to metal, increasing the recyclability and sustainability of their product range.12

Numerous can coating technologies have been developed to meet the demands of consumers and the packaging requirements of brand owners. The most common can coating technologies are epoxy, polyester or acrylic based. Epoxy coatings have long been preferred as the superior technology choice for much of the metal packaging industry, owing to their cost competitiveness, robust application and fabrication properties, and excellent corrosion resistance and flavor performance. This is particularly true in the beverage can market, where epoxy coatings offer the best performance for challenging beverage types, such as seltzers, wines, high-alcohol products and sparkling waters.

4. DEVELOPING NEXT-GENERATION CAN COATINGS

In recent years the can coating industry has been challenged to develop new technologies that deliver the high performance of traditional epoxies but do not contain Bisphenol A (BPA), a key monomer used in most epoxy coating technologies.

The European Food Safety Authority is currently considering a proposal that seeks to limit the use of BPA-based products in food contact materials, setting the stage for conversion away from traditional epoxy coatings to newer technologies across Europe.

This transition is challenging for the metal packaging sector. Alternative technologies do not deliver the same level of performance as epoxies, and until recently there were no non-BPA epoxy products on the market. Brand owners are accustomed to the high level of performance offered by BPA-based coatings and have often experienced difficulties in the use of first-generation alternatives, such as those based on acrylic and polyester technologies.

To overcome these challenges, Sherwin-Williams has been working for more than a decade to enable the switch to non-BPA coatings that perform as well as traditional epoxy coatings, identifying solutions that

- Mirror the same performance benefits of epoxy technologies, without the use of BPA

- Are designed as safe technology for use as a food contact material

- Provide excellent metal application, can fabrication properties and product protection

- Are globally recognized as safe for intended uses and as a long-term solution for packaging requirements across the food and beverage, household, and personal care industries

- Provide a one-size-fits-all solution, so that brands do not require multiple can coating technologies for their packaged goods

Sherwin-Williams has been working for more than a decade to enable the switch to non-BPA coatings.

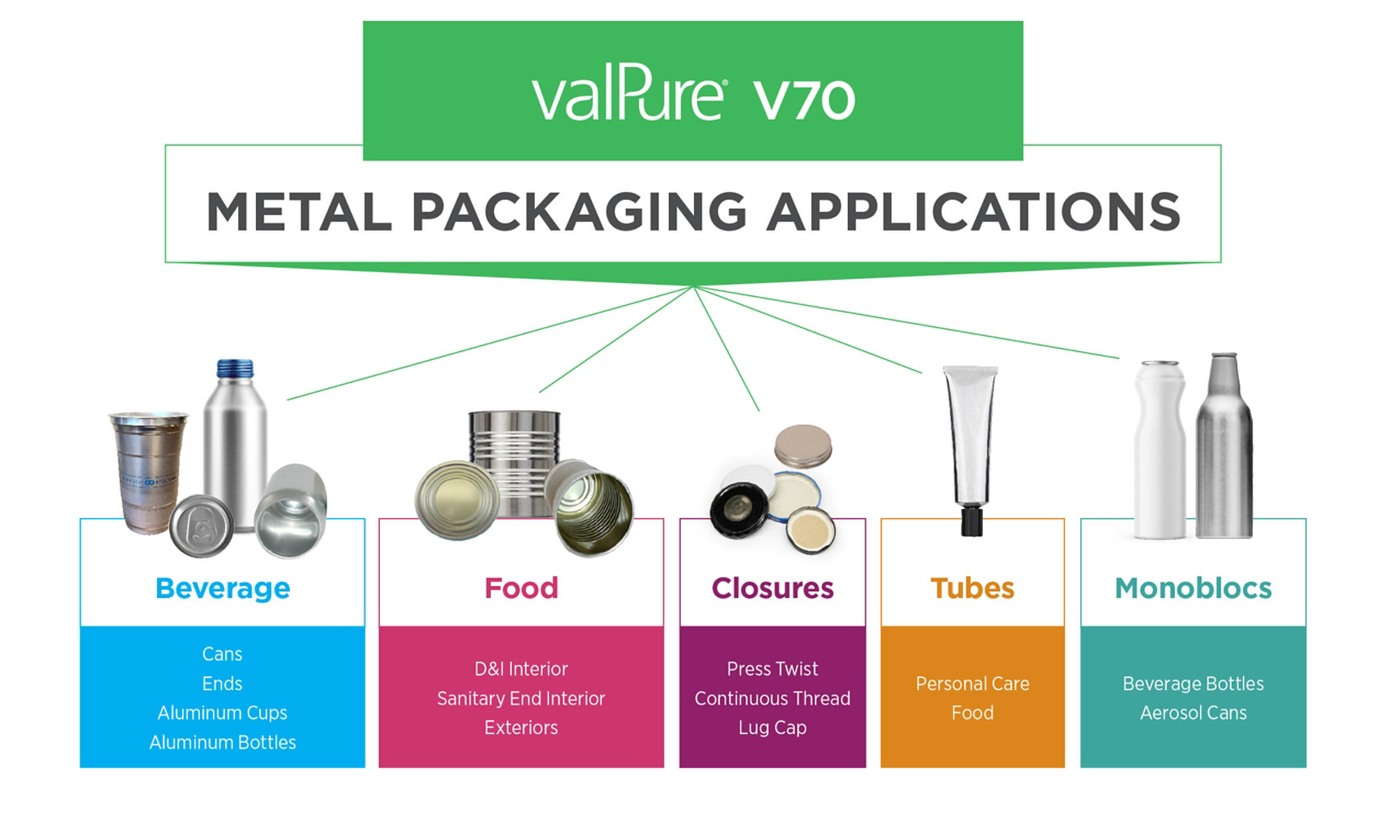

5. SHERWIN-WILLIAMS VALPURE® V70

valPure® V70 was created as a response to these challenges. valPure® V70 is a novel, non-BPA epoxy can coating technology that was developed to deliver the same industry standard performance of epoxy coatings, providing excellent metal application and can fabrication properties and packed product protection without the use of BPA. With over 10 years of research and development, the valPure® V70 non-BPA coatings from Sherwin-Williams are recognized globally as a safe and effective can coating solution that can be used by brands as a long-term solution for their packaging requirements across the food and beverage, household, and personal care industries.

To develop and bring a next generation non-BPA epoxy technology to the market, Sherwin-Williams was aware that it would have to combine its technical expertise with cutting-edge technology to develop a product that could be viewed as a long-term solution for the packaging industry. In addition, Sherwin-Williams would need to build trust and engage a wide range of stakeholders to demonstrate the performance, safety and reliability of such a coating technology.

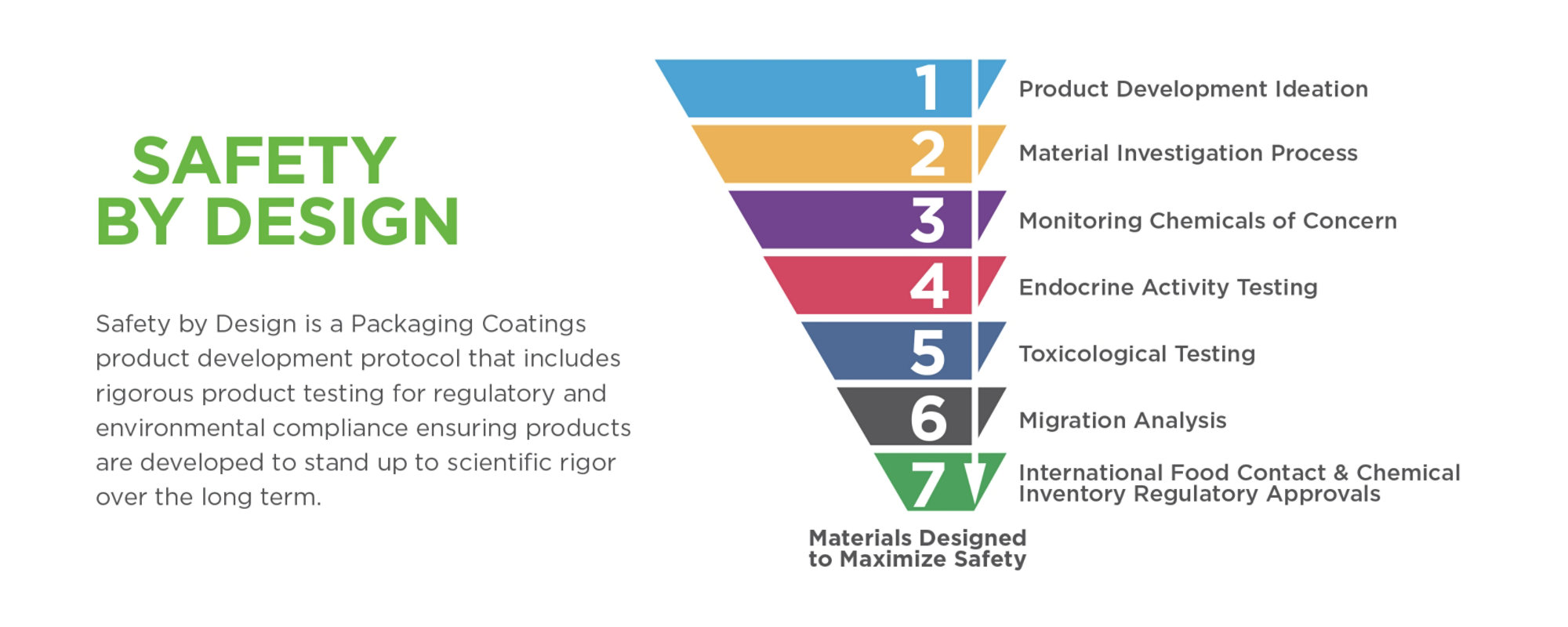

To achieve this, Sherwin-Williams employed its Safety by Design methodology, which is modelled on preclinical pharmaceutical safety evaluations, to develop a new coating technology that focused on the early screening of materials for regulatory compliance. Safety by Design is a material selection process designed to ensure the longevity and safety of new coating technologies. In addition, this process helps to ensure products are developed to stand up to scientific rigor for decades to come. This protocol considers current and emerging regulatory requirements, consumer and brand owner preferences, and state-of-the-art testing to ensure valPure® V70 is viewed as a long-term packaging solution. As part of the product development process, Sherwin-Williams worked openly with Non-Governmental Organizations, independent laboratories, toxicologists and universities to ensure valPure® V70 had independent third-party scrutiny to demonstrate that it was safe for its intended uses, had a reduced environmental impact and was suitable for use as a food contact material.

Through this development process, Sherwin-Williams needed to find a substance that maintained the performance benefits of traditional epoxies without the use of BPA. We identified TMBPF, a starting substance in the development of valPure® V70, as a suitable substitute for BPA in can coatings. In addition to tests prescribed by regulators, Sherwin-Williams has commissioned over 20 independent assessments and tests on the potential impact of TMBPF on human health and the environment. As a result of this extensive testing, TMBPF is a widely researched substance for food contact, and valPure V70 has been approved for food contact applications across the world, including in Europe.

valPure® V70 addresses the many challenges faced by coating manufacturers by offering an innovative, high-performance, solution with excellent application, fabrication and pack performance. As the only non-BPA epoxy coating approved for food contact applications, the Sherwin-Williams valPure® V70 product line enables can manufacturers to switch to non-BPA products without overhauling their manufacturing equipment and processes. The valPure® V70 technology provides a long-term solution for one of the world’s most sustainable forms of packaging, significantly contributing to the ambition of building a fully circular economy, with valPure® V70 proven to work effectively on post-consumer recycled aluminum. It is estimated that aluminum cans contain more than 90 percent recycled content, and valPure® V70 performs well across all types of cans.

Today, valPure® V70 is a preferred solution for can manufacturers and brand owners and is used in billions of cans across the food and beverage, household, and personal care sectors. In line with its commitment to continuously improve its technologies, Sherwin-Williams engaged with the Cradle to Cradle Institute to provide an independent assessment on the safety of valPure® V70.13 The Cradle to Cradle Material Health Certificate recognizes products that avoid the use of harmful chemicals and toxic materials.

valPure® V70 is the only non-BPA epoxy coating technology and the first can coating to achieve Platinum certification, which is recognition of the product's adherence to the highest possible standards in the design and manufacturing process.

valPure® V70 has won and been shortlisted for a number of awards including

- Winner of the Sustainable Innovation Award at the SEAL Awards for its unique role in paving the way towards a sustainable future for the packaging industry

- A silver award for Best Product of the Year by the Global Good Awards in recognition of its positive environmental impact

- Product Innovation of the Year in the prestigious Edie Sustainability Awards — shortlisted for its significant contribution to environmental and sustainability improvements within the industry

valPure® V70 was designed to meet the stringent global regulatory requirements for food contact materials, with robust development and safety testing protocol to achieve approval from international regulatory agencies. valPure® V70 is tested to ensure it meets compliance requirements across the globe and is approved for use in food, beverage, cosmetics and personal care products within Europe, the U.S., Canada, China and Japan.

The development of valPure® V70 is testament to the Sherwin-Williams commitment to sustainability, ensuring that its products contribute to safety and sustainability throughout their life cycle.

6. CASE STUDY — HOW VALPURE® V70 CAN ENABLE THE TRANSITION TO SUSTAINABLE PACKAGING

For aluminum cans to function as a sustainable solution, they require can coatings to protect the quality and integrity of the can and the products they contain.

valPure® V70 has the potential to enable significant change within the food and beverage, household, and personal care industries, which are beginning to favor more sustainable forms of packaging, such as aluminum cans, over other packing types, such as plastic and glass.

According to recent research, about 85 percent of consumers make purchasing decisions with sustainability in mind, and they especially care about packaging, with more than half of consumers saying that packaging must be ecofriendly.14

One of the more recent success stories in the switch to aluminum is the canned water industry, with global companies starting to package some of their water brands within aluminum cans. Supermarkets such as Tesco in Europe have offered canned water since 2018. Some of the U.K.'s biggest food and drink wholesalers, such as Bidfood and Brakes, and have also chosen canned water in response to retailer and customer demands to reduce their plastic packaging.15 According to Metal Packaging Europe, the flavored and mineral waters market is one of the fastest growing in the world; currently valued at over €50 billion globally.16

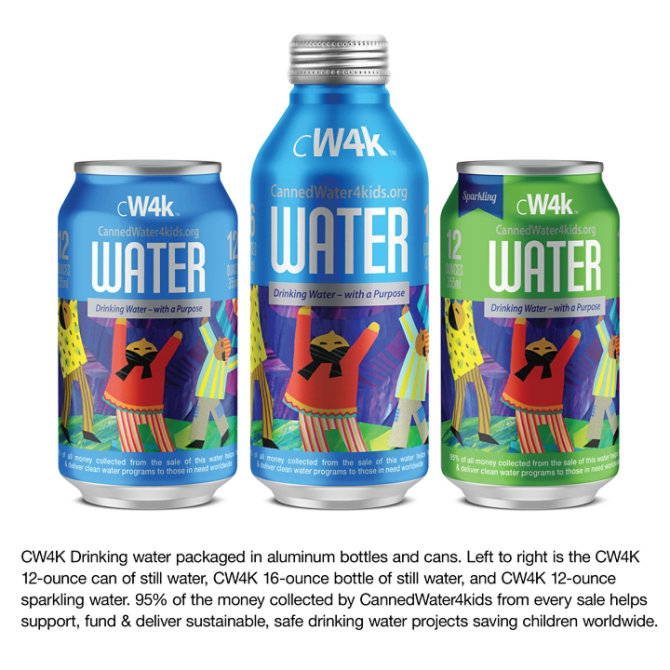

Canned water has been linked to sustainable initiatives and brands with the U.K. brand, Dash, choosing cans for its waters flavored with misshapen fruit that would otherwise be thrown away by supermarkets. CannedWater4kids (CW4K), a nonprofit based in the U.S., which ensures all children across the globe have access to safe drinking water, funds its initiatives through the sale of its drinking water in aluminum bottles and cans.17

valPure® V70 is in full commercial use for some of the most challenging beverage types, including canned water, seltzers, wines, alcoholic beverages and sparkling waters. While canned water may not seem revolutionary, it can be a very technically challenging beverage to pack. This is due to the fact the flavor of canned water is neutral, as it lacks the high levels of sugar and flavorings found in other beverages. This means that the flavor profile of water could be easily impacted by certain can coating formulas. It is very important that the coatings used for canned water limit migration of materials from the coating which may affect the flavor profile of the water. Historically, BPA-based epoxy coatings have been the preferred coating to hold canned water due to the robust sensory performance of epoxy coatings.

Sherwin-Williams has worked closely with its customers to test a range of different coating formulas to successfully pack water in metal packaging. valPure® V70, as an epoxy technology, has performed well when used as a coating for canned water, making it the perfect partner to enable the growth of this exciting packaging sector.

Within the diverse range of brands and sub-sectors of the beverage industry, there is another key player that faces many challenges in transitioning to sustainable packaging – the wine industry.

Traditionally, the wine industry has favored the glass bottle. According to a recent study, bottling represents the largest percentage of greenhouse gas emissions relating to the production of wine.18 As the wine industry attempts to reduce its carbon footprint, half of its greenhouse gas emissions are attributed to the manufacture and transportation of glass bottles, which are created in energy-intensive furnaces.19

Glass is still the most practical packaging for inert wines that are meant to age over time in a cellar. However, for the 95 percent of all wine consumed within months of purchase, bottles are increasingly impractical with many wine producers reporting shortages of glass bottles.20 Some people in the industry, however, remain skeptical about the can, with some wine experts claiming that drinking wine from a can could diminish the quality and aroma of the wine.

Despite these concerns, the wine industry is increasingly considering metal packaging as a viable alternative, with cans valued for their sustainability benefits. The value of the global canned wine market is estimated to surpass €525 million ($570 million) by 2028, at an average annual 13 percent growth.20

While glass is technically highly recyclable, in the U.S., only 31 percent of glass is recycled. However, aluminum is widely recycled with almost 75 percent of the aluminum that has ever been produced is still in use today.21

The manufacturing of such cans for the industry is also significantly more efficient, with the production of three 25cl aluminum cans, instead of a traditional 75cl wine bottle, reducing carbon emissions by 79%.22 Additionally, according to a survey by the Swedish government’s alcohol retail chain Systembolaget, reported in the Financial Times, a can is “28 times more efficient to recycle than bottles.” Cans of wine are smaller, lighter, more durable, and easier to store and recycle.22

However, for the wine industry to successfully transition to metal packaging, it needs innovative can coating technologies that protect its product, support shelf life, and do not impact the taste or quality of the wine. Maintaining the quality of wine in cans is challenging since many wines are very acidic and can degrade internal can coatings. This can lead to corrosion of the can, which can adversely affect the flavor of the wine. Coatings also need to be suitably flexible to avoid cracking during the sealing of the can. Cracks in the coating can lead to exposed aluminum, which can react with the sulfite preservatives in the wine to form hydrogen sulfide, which has a very unpleasant odor. Therefore, for a coating to be suitable to protect canned wine, it must be able to provide a strong barrier between the wine and the aluminum can and be flexible enough to remain intact during the sealing process. valPure® V70 is proven to have excellent barrier resistance and flexibility. This combination of properties makes valPure® V70 very effective for canned wine.

Indeed, for metal packaging to work successfully as a sustainable solution for the food and beverage industry, innovative can coatings are essential for preserving the integrity of these cans and the products they hold. The development of valPure® V70 supports this transition towards the increased use of metal packaging for the wine and water beverage sectors, offering an epoxy technology without the use of BPA.

7. CONCLUSION

The metal can is critical to support a sustainable packaging supply chain in Europe. Valued by brand owners and retailers alike, canned goods provide safe, high-quality food with a multiyear shelf life, significantly reducing food waste. Furthermore, metal packaging is a critical packaging type for achieving circularity within the food and beverage, household, and personal care industries. Collectively, 98 billion units of metal packaging are manufactured each year in Europe for the food and beverage, health and beauty, household, and industrial markets, which represents 15 percent of the European packaging market.23

However, metal packaging and aluminum cans cannot provide these benefits without innovative can coating technologies, which protect the integrity of the can and provide a protective barrier for the product. Can coating manufacturers, such as Sherwin-Williams, are constantly innovating new coating solutions that meet the ambitious demands of brand owners, who are looking to use metal packaging as their preferred packaging type.

Sherwin-Williams valPure® V70 non-BPA epoxy technology demonstrates the Company’s drive to develop innovative, safe and sustainable coating technologies. The valPure® V70 technology delivers the industry standard performance of epoxy coatings, providing excellent application, can fabrication properties and product protection. valPure® V70 from Sherwin-Williams provides a long-term solution for the future of sustainable packaging and the circular economy.

As the EU strives to reach the ambitious goals enshrined within the European Green Deal and the Circular Economy Action Plan, policymakers and regulators continue to push for the prioritisation of a sustainable packaging industry. Sherwin-Williams will remain a key partner in this journey, continuing to innovate in order to ensure that its can coating technologies can meet Europe’s future sustainable packaging requirements and support a fully circular European economy.

APPENDIX

- https://www.unep.org/plastic-pollution#:~:text=Plastic%20pollution%20can%20alter%20habitats,t%20exist%20in%20a%20vacuum

- https://www.cantechonline.com/news/28082/research-forecasts-europe-metal-cans-market-Growth/#:~:text=Europeans%20use%20up%20to%2050,drinks%2C%20and%20alcohol%2Fbeer

- https://thinkcans.net/aluminium/10-aluminium-facts

- https://thinkcans.net/aluminium/10-aluminium-facts

- https://www.metalpackagingeurope.org/article/metal-packaging-reducing-waste

- https://international-aluminium.org/wp-content/uploads/2022/02/Aluminium-vs-glass-and-plastic-FINAL-Information-Sheet-1.pdf

- https://www.waste360.com/aluminum/why-aluminum-packaging-use-rise-part-2

- https://thinkcans.net/aluminium/10-aluminium-facts

- https://food.ec.europa.eu/safety/food-waste_en

- https://eeb.org/eu-wastes-more-food-than-it-imports-says-new-report/

- https://www.cancentral.com/sites/cancentral.com/files/public-documents/CMI_OnePager_10Reasons_Metal%20Cans%202022.pdf

- https://www.coatingsworld.com/issues/2022-04-01/view_features/passing-the-baton-from-plastic-to-metal-packaging/

- https://c2ccertified.org/the-standard

- https://www.waste360.com/aluminum/why-aluminum-packaging-use-rise-part-1

- https://packagingeurope.com/tesco-invests-in-canned-water/4444.article

- https://www.metalpackagingeurope.org/article/premium-flavoured-mineral-waters-yes-we-can

- https://www.cannedwater4kids.org/2019/08/drinking-water-with-a-purpose/

- https://www.sciencedirect.com/science/article/pii/S2772801322000173

- https://www.nytimes.com/2021/06/10/dining/drinks/wine-bottles-climate-change.html

- https://www.ft.com/content/10a02cf2-dd3c-4426-83ac-5d123dcbaaa2

- https://www.theguardian.com/us-news/2023/jan/09/canned-wine-industry-environment

- https://www.ft.com/content/10a02cf2-dd3c-4426-83ac-5d123dcbaaa2

- https://www.metalpackagingeurope.org/metal-packaging

Download a Copy of the White Paper

Download the full "Can coatings: unlocking the future of sustainable packaging" white paper which highlights the critical role of innovative can coating technologies for the infinitely recyclable metal can, such as valPure® V70 non-BPA coatings from Sherwin-Williams.

Have a Question?

Ask how Sherwin-Williams can bring the right products, technical service and regulatory expertise for your packaging application.

Related Products

valPure V70 - a non-BPA Epoxy

Cutting-edge Non-BPA Epoxy technology available for Beverage Can Interior, Beverage End Interior, Food D&I Interior, and Food Exterior and interior monobloc applications (V70 Series).