Innovation

A history of innovative, patented technologies for the packaging industry.

Learn about our Safety by Design Development Protocol

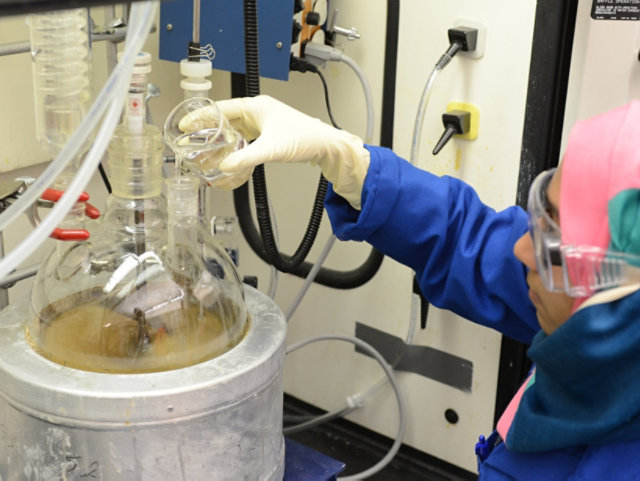

Sherwin-Williams is constantly striving to bring innovative, market-ready technologies to life. Our innovation strategy benefits from a tremendous capacity for polymer development, and makes safety and product stewardship a primary concern.

The actual process of bringing a new technology to market is lengthy. It follows a rigorous protocol that takes place on a global level. The first step in the process is to outline our goals, and the last is a thorough validation phase to test performance, consistent quality, ease of use and safety.

Investments in new technology development allow us to focus on making advances in many areas, including:

Enhancing Product Performance and Quality: We’re always on the forefront of new ways to improve durability and content preservation.

Aligning with Consumer Trends and Preferences: Sherwin-Williams stays on top of changing consumer trends and preferences through market research and product development.

Anticipating and Adapting to Global Regulations: Compliance is a constant concern in our industry. With our vast regulatory knowledge, an international footprint, and leading-edge research and technology, we’re adept at predicting and adapting to changing regulations.

Sherwin-Williams is a technology leader in the industry, with more than 400 patents including 49 non-BPA* patents, proven expertise in navigating the regulatory landscape and a body of highly engaged stakeholders. Sherwin-Williams has unmatched capabilities and expertise in non-BPA coatings, with 40 non-BPA regulatory approvals - the most in the industry.

FDA and EFSA’s safety review of scientific evidence continues to support the safety of current BPA usage in food containers and packaging. However, consumer and brand owner demand for non-BPA coatings is growing, and regulatory restrictions have limited the geographies and uses for BPA-containing coatings.

valPure V70 - a non-BPA Epoxy

Learn more about valPure V70, our patented non-BPA epoxy technology innovation.

How did we develop V70?

Tom Mallen, Vice President of Compliance and Technology Marketing for the Global Packaging Division tells us in an article published in Chemical Watch.

Coatings manufacturer Sherwin-Williams (formerly Valspar) wanted to develop a new food can lining that didn’t raise health concerns, so it took the unusual step of asking environmental and safety advocacy groups for their advice. The company shared its information on alternatives, asked advocates to recommend more studies, used scientists they recommended to conduct those studies and allowed those researchers to independently publish their views - all in a nod to a changing marketplace with many voices on product safety.

"Our equipment has been used in the inside spray application of the valPure V70 materials. This experience at full production speeds has shown that the material can be successfully applied to aluminium beverage cans without significant equipment changes or modifications when following the recommended procedures provided by Sherwin-Williams Packaging Coatings,” said the company’s representative.