How to Extend the Service Life of Protective Coatings in Subsea Environments

Durability and Compatibility of Protective Coatings Prolong Well Production Capabilities

by Travis Crotwell, Business Development Manager – Upstream Oil & Gas, Sherwin-Williams Protective & Marine

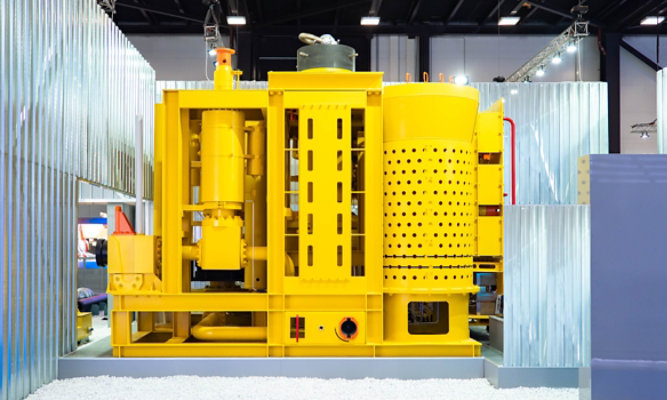

Hundreds and even thousands of feet beneath the ocean’s surface, subsea oil and gas production equipment churns on the sea floor and below, extracting valuable resources from wells and pumping them to nearby production and storage operations situated on the surface. While several wells may be drilled within a given area, it is not financially viable to deploy multiple offshore platforms to accommodate these different reservoirs. Instead, oil and gas producers use subsea tiebacks to connect each reservoir to a single existing processing operation, which may be as far as 30 miles away.

Such tiebacks involve a large amount of subsea equipment responsible for pressurising systems, maintaining high temperatures, separating solids and fluids, and other activities related to extracting raw materials from the earth and pumping them to fixed platforms and floating production storage and offloading (FPSO) vessels. The longer this equipment can operate without requiring service, the better. And that timeline needs to at least match the projected service life of the producing field. That way, oil and gas producers won’t need to pull equipment up for intermediate service at a great cost.

Given the common 25-year life or more for many oil and gas reservoirs, producers expect that life or longer from not just the equipment itself, but also the coatings applied to protect that equipment from corrosion. If those coatings fail prematurely, so can the equipment, causing major productivity and monetary losses for a reservoir that can reduce its overall return on investment. With today’s reservoirs now reaching 30-year service lives or longer, producers need to consider more robust protective coating technologies at the outset to help extend the life of their subsea equipment. Doing so will help them keep equipment submerged for the duration of the reservoir’s life, reducing the total cost of operation for subsea tiebacks and helping producers protect the bottom line.

The Need for Robust Coatings to Protect Delicate Equipment

When companies identify a new reservoir for oil or natural gas production, they conduct analyses to determine the anticipated service life of the producing field. In many cases, the reservoir could be expected to produce oil for more than two decades, providing a general 25-year guideline for protecting delicate and highly expensive subsea drilling and production equipment so it can operate reliably for the life of the reservoir. However, due to the increasing trend for subsea tiebacks further extending the service life of specific fields, that lifespan is broadening in some reservoirs. Now, 30-plus years of service is becoming a more common longevity target that equipment producers and coatings manufacturers must meet to ensure stable, uninterrupted performance.

Subjected to a broad range of stresses throughout its service life, subsea equipment is often pressurised, faces high operating temperatures and endures transport and submersion in harsh, corrosive marine environments. In these operating conditions, coating systems must provide durability, longevity and protection from corrosion regardless of the type of equipment they protect and whether or not cathodic protection is available as backup protection. Yet, the stakes are the highest on pressurised equipment, as a coating failure that leads to corrosion on such equipment could have catastrophic consequences.

To ensure all equipment will provide safe and reliable performance for the duration of a reservoir’s service life, the oil and gas industry follows established standards and requirements. They include those governed by the International Organization for Standardization (ISO), the CSA Group, NORSOK and NACE International, as well as supplemental requirements prescribed by operators such as Saudi Aramco, Shell and Chevron. The standards and specifications for each installation will depend on the parameters of the project, each stemming from the baseline requirements of ISO, NORSOK and others.

Mitigating Operational and Transportation Stresses

The durability of subsea equipment is tested by a broad range of challenges and stresses, including being pressurised due to its location on the sea floor. Submerged underwater for two to three decades, all coated equipment must be sufficiently resistant to corrosion, while also withstanding the extreme demands involved in undersea oil and gas extraction. That includes ensuring coatings are resistant to impacts, abrasion and water permeation. It also means coatings need to be resistant to the extreme high temperatures of the extracted oil, as well as compatible with the various insulation systems – including thick, seamless silicone systems – installed over top of pipes and equipment to keep that oil hot for below-sea processing and transportation to the surface. These coating properties are crucial not only to ensuring the service life of subsea equipment, but also to maintaining a high degree of performance and return on investment.

Sherwin-Williams offers a comprehensive range of liquid coatings to accommodate the diverse needs of subsea oil and gas equipment, including a range of operational temperature exposures. Both Macropoxy® 646 fast cure epoxy and Macropoxy M922 epoxy glass flake have been tested to NORSOK M-501, Rev. 6, Category 7B standards and can be used on structural components that do not operate at high temperatures. For components that are operating at higher temperatures, Sherwin-Williams features a range of coatings tested to NORSOK M-501, Rev. 6, Category 7C guidelines, all of which are typically used under insulation. The systems include Macropoxy M922, which can accommodate temperatures up to 80°C (176°F), and Dura-Sub™ C1330 epoxy, which can be used for operational temperatures up to 180°C (356°F). In addition, Dura-Sub C1230 epoxy can accommodate even higher temperatures up to 200°C (392°F).

While much of the concern about coating durability and longevity for subsea equipment relates to how coatings hold up during the equipment’s service life, producers need to be aware of the stresses those coatings may encounter before they’re ever placed into service. Such equipment must first be built and transported to the location of the well, introducing a separate set of durability specifications. In the event of project delays, some equipment may need to be stored by the fabricator or remain dockside for weeks or months. Prolonged ultraviolet (UV) and atmospheric marine environment exposures during this time may reduce the durability of the applied coatings, potentially taking valuable years off of their protective capabilities and therefore reducing that equipment’s service life.

With this challenge in mind, producers may choose to specify a solution like Dura-Sub C1230 epoxy from Sherwin-Williams Protective & Marine. It has been tested to the NORSOK M-501, Rev. 6, Category 7A for splash zones, which incorporates UV exposure and measures the coating’s UV resistance and overall performance. Over the course of the testing, the coating is exposed to UV rays for three days, followed by three days of salt spray and finally a freeze and thaw. This cycle is repeated for several weeks until the coating has successfully demonstrated its durability for 4,200 hours. Dura-Sub C1230 and other epoxies from Sherwin-Williams get their improved UV resistance from the tight crosslink density of their ultra-high solids novolac resin chemistry.

Compatibility Across Complicated Systems

Subsea installations involve a complex web of valves, piping and connectors that control and channel the flow of oil or gas from a reservoir to the processing facility. In any given subsea production system, various components may be constructed by different original equipment manufacturers (OEMs). The components are then shipped to a fabricator, which assembles the structural elements and various components into a single connected structure. Finally, the fabricator assembles the subsea production system and performs all of the final steps necessary to prepare the system to be placed into service.

Each OEM may maintain different specifications for its components, making coating compatibility crucial. The coatings that are applied to subsea production systems must be compatible across the different industry standards and OEM specs; additionally, the anti-corrosion coatings must be compatible with the insulation that is installed on top of them. In every application, Sherwin-Williams assesses the specifications and compatibility between commonly-used coatings, as well as the specifications of commonly-used insulations in subsea production systems and tiebacks.

HOT Pipeline Coatings for Hotter Offshore Drilling

As oil and gas producers set their sights on increasingly deeper and more challenging areas for offshore drilling, equipment and coatings must be able to withstand challenging environments and increasing temperatures. With each kilometer of depth drilled, the temperature of the extracted contents increases by approximately 25°C (77°F). Older coatings are not able to handle the increased heat exposure of exceptionally deep wells, leading to failures and threatening the safety of the pipeline.

However, new coating solutions have enabled exploration activities to reach new depths. High operating temperature (HOT) fusion-bonded epoxy (FBE) coatings from the Sherwin-Williams Dura-Sub™ C family applied to underwater pipelines can now accommodate operating temperatures up to 180°C (356°F), with room to handle even more extreme temperatures in the future.

HOT FBE coatings balance several interrelated performance properties to withstand high temperatures. Today’s HOT FBE coatings feature higher glass transition temperature (Tg) values, allowing pipeline operators to specify coatings with Tg values that are at least 5°C (9°F) greater than the highest operational temperature of the pipe. This ensures that the coatings will remain hard and glasslike with better adhesion. However, new HOT FBE coatings also maintain a high degree of flexibility despite their high Tg values; this ensures that pipes can be joined onshore and reel-laid, saving time and money when compared with welding and coating field joints offshore from a barge. High Tg values also provide a stronger barrier against water and corrosion-causing particles, in addition to stronger damage resistance.

A given project will use a specific type of insulation based on project requirements: for example, either glass syntactic polyurethane or a silicone-based thermal insulation for higher operating temperatures. Fabricators may need to address a transition point between the anti-corrosion coatings and insulation, and a coatings supplier can help the fabricator determine compatibility and identify an appropriate specification for the two materials.

As equipment fabricators and assemblers apply and reapply coatings to subsea production systems, they must work as efficiently as possible to avoid delays and keep equipment moving through their facilities. Sherwin-Williams helps fabricators reduce the coating time required during production by prequalifying coatings to the necessary specifications. Additionally, Sherwin-Williams is enabling fabricators to realize faster curing times by using ultra-high-solids (UHS) liquid epoxies. UHS coatings reduce the amount of solvent that needs to evaporate, helping them cure more quickly than products with 70% to 75% volume solids. With UHS coatings, fabricators can apply the second coat on a much faster timeline and move coated equipment sooner — both key improvements to efficiency.

The insulation used on subsea production systems is commonly a thick, seamless material, and no additional anti-corrosion coatings are used on top of the insulation. But compatibility between the insulation and the anti-corrosion coating applied beneath it is essential to prevent delamination and maintain flow efficiency. While some coatings work well at enabling a strong bond between the coating and insulation, there is room for improvement. As a result, Sherwin-Williams is currently testing new technologies to enhance that bond between the coating and insulation, including new coatings with additional adhesion promoters.

Increased Durability for Subsea Projects

As oil and gas producers look to new opportunities for growth and development, they are challenged to both identify new areas for exploration and to make their existing operations more efficient. High-performance coatings support both of these goals by extending the service life of subsea production systems and other equipment, as well as providing the necessary performance enhancements to withstand increasing temperatures and external stresses.

ABOUT THE AUTHOR

Travis Crotwell is Business Development Manager – Upstream Oil & Gas for Sherwin-Williams Protective & Marine. Crotwell’s responsibilities include serving as a corrosion specialist and providing engineering support for owners, operators and EPC firms. Additionally, he is responsible for market opportunity and market development across the upstream oil and gas market segment. Crotwell has 16 years of industry experience, including 15 years with The Sherwin-Williams Company, previously serving as a Field Technical Service Representative, NACE Coatings Inspector, Protective Coatings Specialist and Project Development Manager. Crotwell is a NACE CIP Certified Coating Inspector, SSPC CCI Certified Coatings Technician and a board member for the SSPC Gulf Coast Chapter. Contact: Travis.M.Crotwell@sherwin.com.

Discover More

Industry Expertise and Innovation

See how we help customers find customised solutions for their project and application challenges.

Our Oil & Gas Expertise

Explore our industry solutions and technology to help protect your assets.

LEARN MOREProduct Lookup

Find out more about our innovative coatings for a variety of industries.

FIND A PRODUCT