sayerlack.mp4

GFX: Sayerlack innovative wood solutions 2k high gloss polyurethane polishing

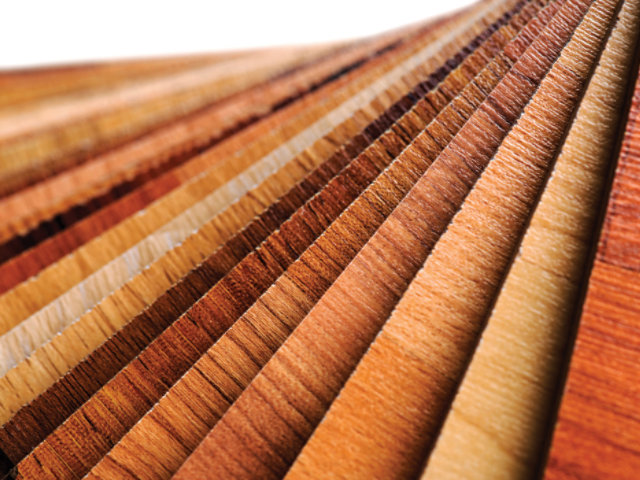

GFX: Finishing materials used SHER-WOOD SB Spray Stain Sayerlack Premium Polyurethane Sealer Sayerlack Premium Polyurethane Clear Topcoat

VO:

[00:00:05] Hello. Today we're going to demonstrate a simplified five step process for buffing and polishing Sayerlack's premium polyurethane for the actual buffing and polishing portion.

[00:00:16] We'll be using equipment braces and just a single polishing compound from our good friends at Mirka USA. All of the materials shown here today are available now for many of our North American Sherwin-Williams industrial wood coatings facilities. For this video today we'll be demonstrating the process on a tabletop that has been pre finished with Sherwood SB spray stain Sayerlack premium polyurethane sanding sealer and Sayerlack premium polyurethane gloss topcoat. Before we start I want to note that this video serves as a general guideline for common practices in minor adjustments can be made depending on many things including the finished type used in woodshop preferences buffing and polishing should be done after adequate dry the finishing system. For this video we've allowed for 48 hours of dry time but as a good practice, always refer to the coating manufacturers data sheet for details. So let's get started.

GFX: Sayerlack innovative wood solutions Surface leveling

[00:01:13] The goal in this first step was to flatten out any texture or minor surface defects. For the step we're using Mirka's micro star P twelve hundred sanding disc over the 90 55 interface pad. Run the machine between 6000 to 8000 RPMs and don't apply too much pressure. The coating should powder up nicely when Sandy.

[00:01:37] Make sure the entire area is wiped clean with water and a lint free microfiber cloth prior to the next sanding step.

GFX: Sayerlack innovative wood solutions Refine

For the second step we're using Mirka's micro star P fifteen hundred sanding disc over the same interface pad to refine the scratch profile left from the surface leveling step.

[00:02:00] You may notice some high spots from the previous stage. Now is the time to flatten them out during the first two sanding steps. You may also notice a pigtail pattern when sanding. This can happen from buildup of debris on the abrasive referred to as Pili. Be sure to remove any pilling from the surface and the abrasive again prior to the next step, make sure the entire area is wiped clean.

GFX: Sayerlack innovative wood solutions Finesse

[00:02:32] For the third step we're using Mirka's Abralon three thousand over the same interface pad to further refine or finesse the finish. For optimal results, Mirka recommends dampening the foam disk with clean water to help the cutting action. Using too much water will result in water slinging from the pad causing the abrasives to float over the surface with reduced cutting action.

[00:03:02] Use a 50 percent overlap pattern seen here. Make sure the entire area is wiped clean with water and a lint free microfiber cloth prior to the next step.

GFX: Sayerlack innovative wood solutions Buff

[00:03:23] For this staff we have switched from the Dearos orbital machine to a rotary variable speed buffer assembled with Mirka's twisted lamb's wool pack. We'll be polishing with Polish shine 10 polishing compound for the step and the final polishing step. Use a slow speed approximately fifteen hundred RPMs for the step to prevent burning into the finish. Use about a nickel sized DAB for two foot by two foot square foot area using a 50 percent overlap pattern seen here.

[00:03:52] If you're slinging compound check your RPMs or cut back on the Polish shine 10 compound. You should really see the gloss start to pop after this step. If you haven't noticed cleanliness is key throughout. So once again make sure the entire area is wiped clean with water and a lint free microfiber cloth.

GFX: Sayerlack innovative wood solutions Polish

[00:04:17] For the final polishing step we're using Mirka's eight inch black foam pad in the same PolarShine 10 compound as the last step. Use a slow speed approximately fifteen hundred RPMs and use the same amount of compound with 50 percent overlap pattern seen here again. We feel it's beneficial to note that throughout product trials using the Sayerlack polyurethane in Mirka products we discovered that we could simplify the process in reducing the number of steps and skews once again make sure the entire area is wiped clean with water and lint free microfiber cloth.

[00:04:56] Enjoy. And thank you for watching our video today.

GFX: Sayerlack Innovative Wood Solutions For more information Please visit www.oem.sherwin-williams.com/products/wood