Sherwin Williams Waterborne_V1.mp4

Christina: [00:00:00] Joining me now is Joe Kujawski from Sherwin-Williams. Joe thank you so much for joining me.

Joe: [00:00:05] You're welcome Christina.

GFX: IWFTV Christina Jensen Host

Christina: [00:00:06] So I want to talk about waterborne coatings there's a lot of buzz surrounding it. You know this is a two part question. Why do you think this is and what's being done to improve it?

GFX: Joe Kujawski Sherwin-Williams

Joe: [00:00:15] Right. There's a number of factors driving demand for waterborne coatings technology right now Christina. Number one is the coatings themselves have gotten a lot better. The application characteristics are a lot easier to work with. The performance of the coatings has improved greatly. You know Sherwin-Williams is on our seventh generation of waterborne coatings we've been creating waterborne coatings since the early 1980s and they've just gotten the dry time is a lot faster they sand into a nice white powder. They flow and level beautifully. They're very scratch resistant and durable. They just come a long way. So that's one thing driving demand for waterborne coatings.

Christina: [00:00:49] Can you talk about what Sherwin-Williams is working on in terms of waterborne technology?

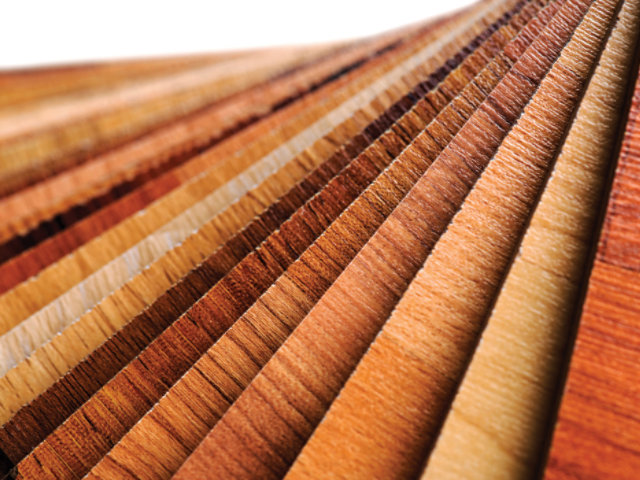

Joe: [00:00:54] Yeah. We've got a number of new products that we've launched lately with waterborne technology. One of our most popular products is our new Sherwood waterborne universal primer. And it's a great white primer. It's universal because you can prime virtually any species of wood with it. It also does a great job priming and sealing MDF. So it's a great choice to go to and you know when you think about the finishing process for wood a kitchen cabinet manufacturer that white primer that they use as a staple I mean they use a lot of the White primer. So replacing their basic white primer with a waterborne primer switching from solvent born to waterborne is a great start to getting their VOCs down. Other products that we have that are very popular on the waterborne side are these Sherwood water reducible wiping stain that's a water base wiping stain that has a lot of open time so you can rub it into the wood for a long time but it still dries fast enough that it's for good high production finishing lines. And then finally you know probably my favorite product that we've launched recently is the Sayerlack Hydro Plus. Hydro Plus is a clear topcoat based on advanced European technology. This is a high performance clear that just flows in levels really good has a great look to it dries quickly. Most customers use it right out of the package right out of the can but it can be catalyse for better durability and for faster dry. So those are three great products that get started with on waterborne.

Christina: [00:02:22] I want to talk a little bit about manufacturers you have mentioned them previously. What are other ways that they can implement waterborne coatings.

Joe: [00:02:29] Well when switching to waterborne coatings I think the most important thing to do is to make sure you partner with a supplier that is experienced in waterborne coatings and Sherwin-Williams is a great partner to select for that purpose. We've been converting customers to waterborne for a long time. In fact Sherwin-Williams has our waterborne transition team. And this is a this is a team of experts that will come to a manufacturer of a wood product and they'll help match all their stain colors. They'll help dial in all their equipment get their sanding process correct and they'll help create new standards for the customer. Do a line audit to make sure that they're running their line as efficiently as possible as they switch to waterborne.

Christina: [00:03:11] Sounds like Sherwin-Williams is doing some great things.

Joe: [00:03:12] Yeah we are we are.

Christina: [00:03:13] All right. Well thank you so much for joining us. I'm Christina Jensen for IWM TV.