DFV Industrial Coating and Wood-effect Decorations Certified and Guaranteed for up to 15 Years

Syntha Pulvin® Powder Coatings For Architectural Use

DFV Group realises all their finishes only using Qualicoat approved non-toxic polyester powders. In this regard, the continuous collaboration with suppliers of powder coatings is fundamental, such as Sherwin-Williams, strategic partners in the creation of excellent products and in the research and development of cutting-edge solutions, capable of responding promptly to the changing needs of the market.

DFV is an Italian group with a strong international presence, and a leader in the coating and decoration of aluminum profiles and laminates for architectural and industrial use.

Founded in 1972, DFV currently operates 4 production units in Italy (Lecce, Venice, Bari, and Agrigento), 2 in Brazil (São Paulo and Florianópolis), and 1 in Australia (Sydney). All production sites are equipped with modern vertical and horizontal coating systems, as well as wood-effect decoration technologies, enabling DFV to offer a wide range of high-quality colours to several thousand customers, including window fabricators, aluminum profile distributors, manufacturers, and system designers for residential and industrial architecture.

DFV’s product range includes classic and special RAL colours, wood-effect coatings, and decorative finishes. The company’s core business is represented by its patented EZY and EZY HD2 wood-effect decorations, developed using powder-on-powder technology. DFV offers all coating and decoration technologies for aluminum: RAL, powder-on-powder EZY, EZY HD, sublimated finishes.

The partnership between DFV and Sherwin-Williams began in the early 2000s. The Companies collaborate for the realisation of wood-effect products, many speckled effect coatings, now also developed in Qualicoat Class 2 version, and the whole range of finishes for architectural. The Syntha Pulvin® powders used by DFV are suitable for architectural use and are Qualicoat and GSB approved.

THE SUSTAINABLE WORLD OF DFV COLOUR

DFV has developed an innovative and sustainable production model, “Made DFV,” implemented across all its Italian and international facilities. This model involves the entire aluminum supply chain, from profile extrusion to coating and building systems.

A strong focus on quality, technological innovation, and energy consumption optimization is a cornerstone of the company’s strategy.

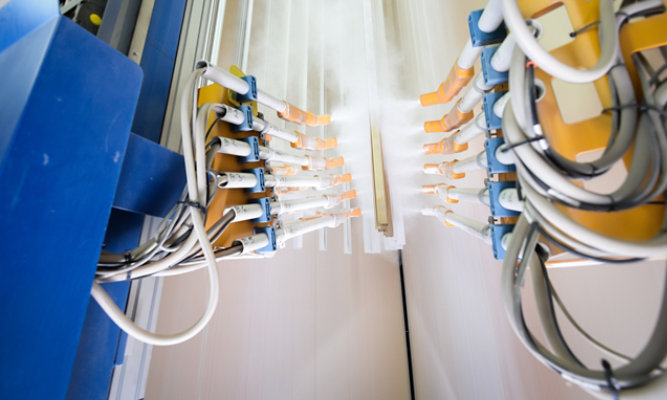

DFV plants are equipped with large automated and compactable warehouses directly connected to the coating lines, optimizing material storage and handling.

Multi-column automated warehouses located next to the coating booths allow powder coating boxes to be stored close to the point of use. This enables operators to independently retrieve the required amount of raw material when needed, reducing downtime and minimizing picking or identification errors.

Careful planning and strict control of every stage of the production process from picking raw aluminum profiles to packaging the coated ones ensure efficiency and high quality of the finished product, verified daily through tests and sampling on each production batch.

The adoption of innovative product practices, such as patented wood-effect decoration technologies Ezy® and the use of Class 2 powders, allows the development of high-performance aesthetic and functional solutions, with a certified and guaranteed lifespan of up to 15 years.

Videos

Industrial Coatings Videos

Learn more about industrial coatings from Sherwin-Williams

Contact Us

Thank you for your interest in Sherwin-Williams Industrial products.

Questions, concerns or thoughts about Sherwin-Williams industrial coatings? Reach out directly or send us a message and we'll be in touch soon.

CONTACT GI EMEAI MARKETING TEAM

gi.emeai.marketing@sherwin.com