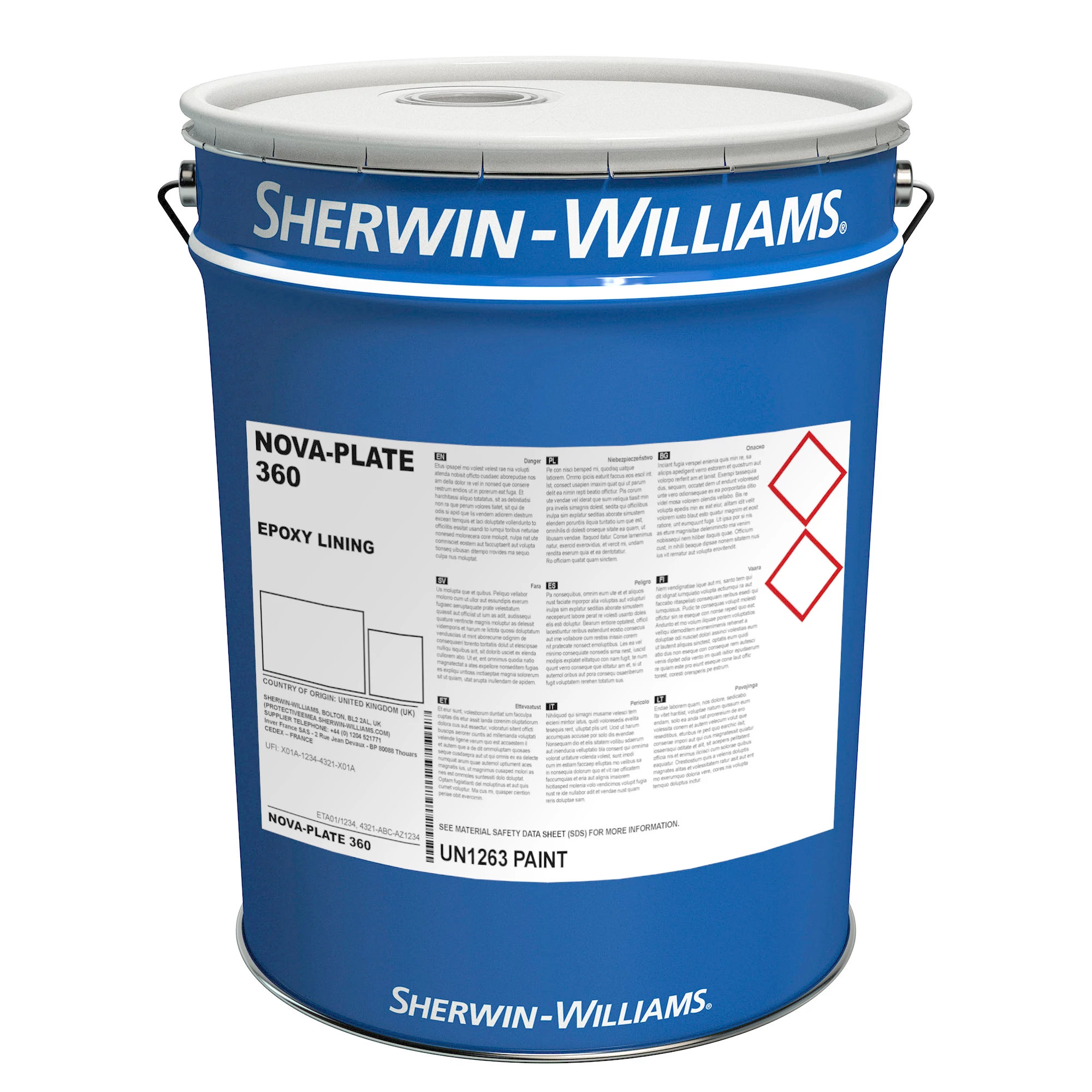

Nova-Plate® 360

A two-component, PFTE, inert, flake-reinforced novolac tank lining.

Nova-Plate® 360 can be applied by single-leg airless or plural-component airless application with the return to service times in as little as 24 hours. It has excellent abrasion resistance and it incorporates Opti-Check™, Optical Activated Pigments (OAP) technology to improve the accuracy and productivity of holiday detection.

Contact Us - To learn more

Reach out to learn more about our products, or use our Data Sheet search to find the latest TDS and SDS content in any language

Data SheetsMore Details

Benefits

- Highly versatile, API-compliant, flake-reinforced, novolac-based tank lining

- High performance in abrasive environments through PTFE (commonly known commercially as Teflon) enhancement

- Low surface energy lining with superior cleaning properties in shutdown

- Single or plural application with coloured hardener to confirm accurate mixing

- Fast 24-hour return to service with an extended recoat window

- Resistance to strong solvents, high temperature and abrasive environment

- Single or multi-coat application up to 50 mils (1250μm) (depending on the intended service)

- Extended pot life

- High-temperature immersion up to 275°F (135°C)

- Optional Optically Active Pigments (OAP) to reduce time and expense in the inspection process

- Applications in multiple market segments requiring superior chemical and abrasion resistance

Brand

Industry

- Power Generation

- Rail

- Oil and Gas

Technology

Technical Data Table

| Chemistry | Epoxy |

|---|---|

| VOC | <100 g/L (0,83 Lb/Gal) |

Product data is a representative set of attributes and characteristics for this system or product line. Data for individual products may vary and is subject to change. Please reference the individual product datasheet for exact specifications on the Datasheets tab above or through Search.