Tank Linings for Biofuel Production

Storing up trouble?

Michael Harrison, Global Product Director - Linings at Sherwin-Williams explores how storing feedstocks for biofuel production presents distinct challenges for the specification of tank linings.

According to the International Energy Agency (IEA), biofuel use is growing at around 6% a year and annual production was up 11% across the decade to 2017. However, storing the lipid feedstocks necessary for the production of biodiesel, renewable diesels and sustainable aviation fuels presents significant challenges for refiners, according to tests conducted by linings and coatings expert, Sherwin-Williams. To avoid the degradation of tank linings and the subsequent corrosion of storage tanks and contamination of feedstocks, it is essential that proper consideration is given to the particular requirements of storing these materials, including type of feedstock being stored, operating temperature and storage duration. Failing to do so risks material contamination, tank corrosion and even production delays.

The growing importance of biofuels

Biofuels have an important role to play in decarbonising transport by providing a low-carbon solution for existing technologies, such as light-duty vehicles in the near term and heavy-duty trucks, ships and aircraft over the longer term. Indeed, according to the IEA, biofuel demand in 2022 reached a record high of 4.3 EJ (170,000 million litres), surpassing levels last seen in 2019 before the COVID-19 pandemic. A significant increase in biofuel production is required to meet Net Zero Emissions (NZE) goals in 2050, and to meet the NZE scenario, biofuel production would need to reach over 10 EJ by 2030, requiring an average growth of around 11% per year.

Importantly, advanced feedstock usage would also need to increase to meet NZE by 2050: biofuels produced from waste, residues and non-food energy crops would have to meet over 40% of total biofuel demand by 2030, up from only around 9% in 2021 – a significant increase.

Storage challenges around biofuel feedstocks

Increasing biofuel production presents one significant challenge for refiners, however: the lipid feedstocks required for biofuel refining have very different chemistries to fossil-based feedstocks, and it cannot be assumed that storage conditions - and the linings systems of storage tanks, in particular - are the same.

To understand the issues faced by biofuel producers, the leading global paint and coating manufacturer Sherwin-Williams has conducted a series of tests that revealed significant degradation of tank linings over time and at certain temperatures, raising important questions for refiners about how they store the feedstocks necessary for biofuel production - and the temperatures to which they are exposed.

The testing process

Sherwin-Williams carried out a two-stage test under NACE TM-0174 Procedure B, with test temperatures of 71°C [160°F], 82°C [180°F] and 93°C [200°F] (based on project specifications) with evaluation at three monthly intervals extending to a minimum of 24 months.

The tank lining systems evaluated in Sherwin-Williams’ test included proven systems used in typical fossil fuel-derived feedstock storage applications: Solvent Free Epoxy Phenolic; Solvent Free Epoxy Novolac; and Novolac Vinyl Ester Glass Flake.

Feedstock media tested included a combination of waste cooking oil; waste cooking oil +1% water; beef tallow; and beef tallow + 1% water. It is reported that the presence of water accelerates the formation of free fatty acids, especially at higher temperatures.

Test results (phase 1)

Under phase one of the tests, the impact of higher temperatures on the test samples was apparent at relatively short exposure times. The effects of higher temperatures on solvent-free Epoxy Phenolic (which is rated to 135°C [275°F] in crude oil) were apparent at 71°C [160°F]. The effects of higher temperatures on solvent free Epoxy Novolac (rated to 149°C [300°F] in crude oil) were apparent at ~82°C [180°F]. Both lining systems failed at 93°C [200°F].

Broadly speaking, subjecting lipid feedstocks to temperatures above 60°C [140°F] results in the production of Free Fatty Acids (FFAs) in lipid feedstocks, and the tests again revealed lower limits for these same two linings, with resistance up to 71°C [160°F] and degradation above this temperature.

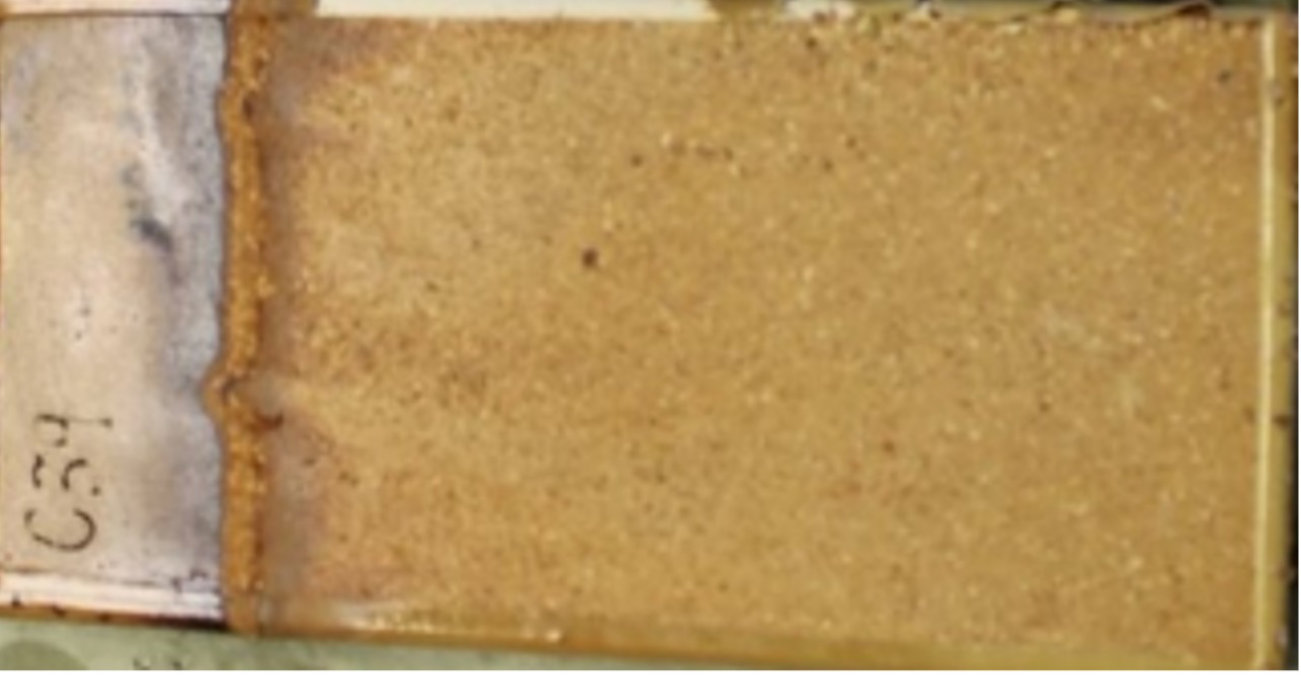

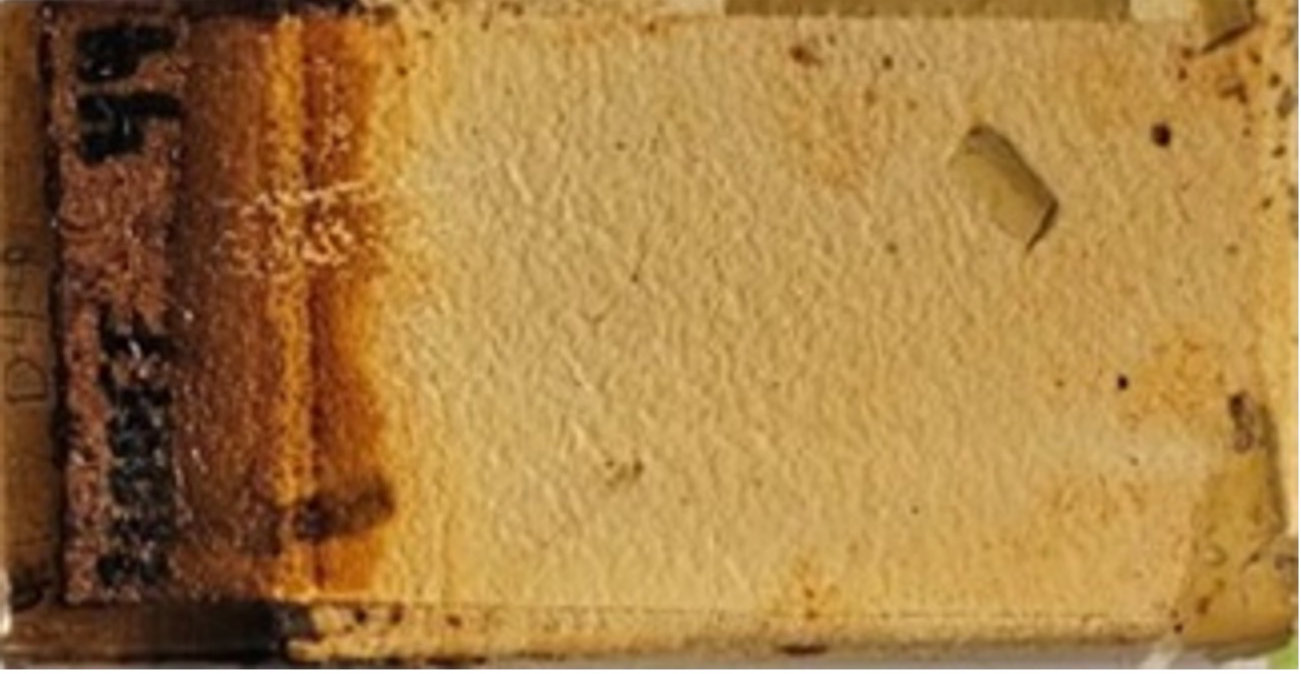

Waste Cooking Oil + 1% Deionised Water (DI)

Example at 71°C

Example at 82°C

Example at 93°C

Test results (phase 2)

A second stage of testing involved two further elements: the examination of the oil composition and how it changes at different temperatures, and the expansion of feedstocks to simulate the conditions in the earlier (water cooking oil) tests.

Analysis of the oil composition revealed that, up to 60°C [140°F], vegetable oils remain reasonably stable with minimal degradation to FFAs after six months exposure. FFAs are thought to be the aggressive component behind degradation and this degradation accelerated at 71°C [160°F] where the oil degrades to ~12% FFA content after six months of exposure. At 82°C [180°F] the formation of FFAs is considerable (>30%). The degradation also appears to be time-dependent, with the FFA level increasing after only three months at temperatures higher than 71°C [160°F]. This shows why there is no immediate breakdown and stresses the need for longer-term testing. (The normal recommended duration as per NACE TM-0174 procedure B is 6 months)

Expanding the feedstocks to simulate the conditions in the earlier (water cooking oil) tests involved the addition of oleic acid to simulate the conditions in the earlier tests, alongside an unmodified control. This revealed a correlation with the results seen for waste cooking oil and beef tallow under phase one when laced with an additional 5% FFA, although samples with higher levels of FFAs showed rapid degradation. Analysis of these modified oils by both time and temperature of exposure clearly showed that the presence of additional FFAs accelerated the degradation of the oil. Indeed, FFA formation grew faster under these conditions.

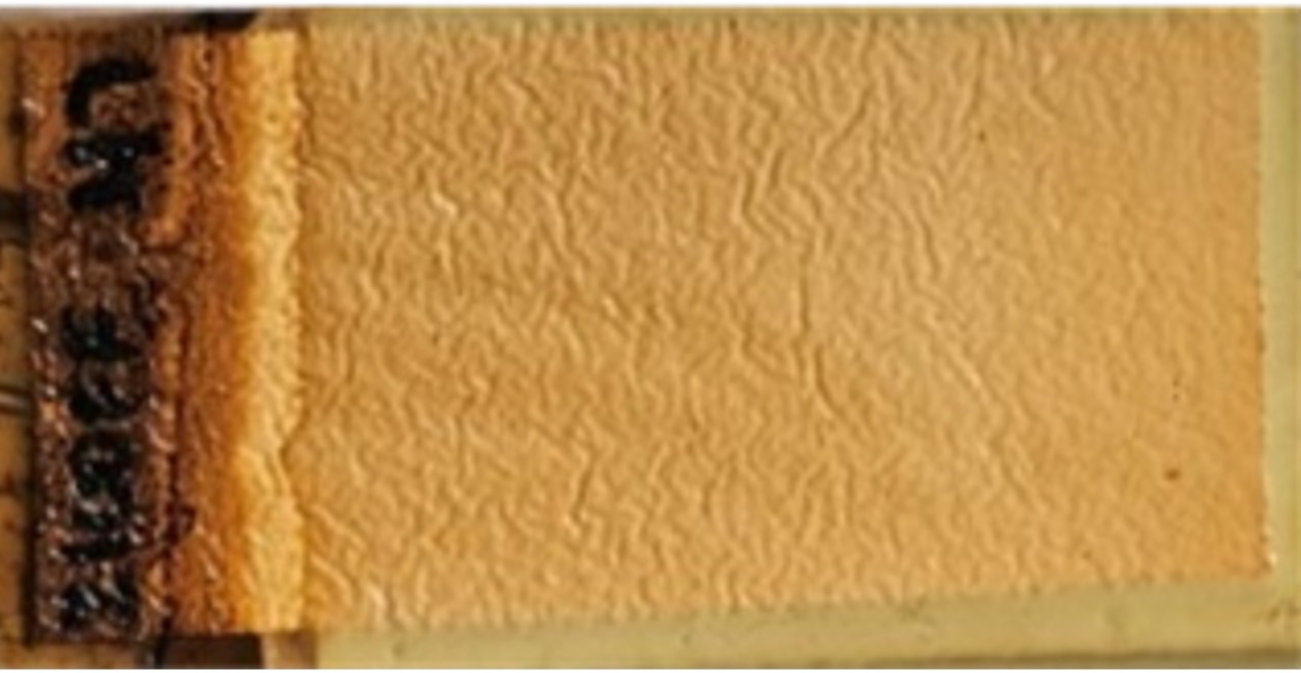

Testing on these oils demonstrates that, as anticipated, a Novolac Vinyl Esters system can handle the higher temperatures primarily due to the superior resistance to organic acids (such as the free fatty acids seen in renewable fuels.) However, they present greater complications (flash point, storage stability etc.) during application.

Example of a Novolac Epoxy

Soy Oil + DI

Soy Oil + DI + 5% FFA

Soy Oil + DI + 10% FFA

Soy Oil + DI + 15% FFA

Example of a Novolac Vinyl Ester Glass Flake

Soy Oil + DI

Soy Oil + DI + 5% FFA

Soy Oil + DI + 10% FFA

Soy Oil + DI + 15% FFA

Conclusion

As the provider of a range of linings proven to resist lipid feedstocks, Sherwin-Williams undertook these tests to better understand the challenges that biofuel producers face when storing feedstocks that are very different from petroleum stocks.

The tests clearly reveal the impact of both time and higher temperatures on tank linings and the negative impact this has on feedstocks, with lining degradation, tank corrosion and feedstock contamination all increasing as temperatures rise, resulting in high FFAs in these feedstocks. Higher rates of FFAs then appear to accelerate degradation. The effect is to create considerable refinement challenges for producers as they seek to increase biofuel production.

It’s important to note that the tests do not call into question NACE TM-0174 Procedure B as the relevant test for these types of feedstock, but the results do raise the question of whether a test duration of six months is sufficient. Longer test periods might be required to gain a more complete understanding of the impact of storing lipid fuel stocks on tank linings.

With biofuel production on the rise and set to grow further as it takes a central role in meeting net zero ambitions, understanding the best practice for lipid feed stock storage is vital. Producers need to be very clear about their storage processes, the temperatures which their feedstocks will be subjected to, and the duration they will be stored. Above all, the exacting demands placed on those storing and handling feedstocks are very different to petroleum ones and must be acknowledged, and the test results show that talking to an expert early on when specifying tank linings for lipid feedstock storage is essential first step for biofuel producers.

References

1. IEA, Tracking Clean Energy Progress Report, July 2023, accessed at https://www.iea.org/energy-system/low-emission-fuels/biofuels

2. Mahmood Ebadian, Susan van Dyk, James D. McMillan, Jack Saddler, Biofuels policies that have encouraged their production and use: An international perspective, Energy Policy, Volume 147, 2020, 111906, ISSN 0301-4215, https://doi.org/10.1016/j.enpol.2020.111906.

Discover More

Industry Expertise and Innovation

Explore customised solutions we deliver for customers to address their project and application challenges.

Article

23 March 2020

Setting the Standard - A Case for Criteria that Simplify Process Vessel Lining Selection