EV Battery Facility Coatings

Driving excellence with protective coatings

Safety Enhancing, durable, protective coatings for EV Battery Manufacturing facilities.

The EV battery industry is complex and rapidly changing and requires fast construction of facilities that can withstand rigorous, chemical- and traffic-intensive manufacturing processes. Our team of EV battery experts will partner with you to streamline coatings and their application processes, create safer, faster, simpler projects and ultimately extend the total lifespan of your facility through:

- Resinous flooring systems that protect against NMP, AGV traffic, moisture

- Specialized flooring systems for highly regulated clean and dry room environments

- Shop applied fire protection and other steel coatings

Sustainable Coatings for EV Battery Manufacturing

Sherwin-Williams is your trusted partner in fast-tracking the future of electric vehicle and battery innovation. We’re committed to safety, quality, efficiency, and sustainability, ensuring automotive and battery technology owners, general contractors, specifying engineers, commercial architects, and other construction partners meet today’s demands while pioneering tomorrow’s EV milestones.

Our Construction Solutions team of EV battery experts will partner with you to streamline processes for:

- Enhanced safety

- Faster construction

- Cost-effectiveness

- Compliance and quality

Optimised Construction Processes for New EV Battery Facilities

EV battery and Automotive factories come with many challenges for construction teams including both for the product and its employees. Protecting your investment is our top priority. From fire protection, to floors, walls and more, Sherwin-Williams offers a wide range of products, solutions, and services to fit your EV Battery and Automotive coatings needs. Watch the video below to see how we are assisting you in creating safer, faster, and simpler EV battery plants.

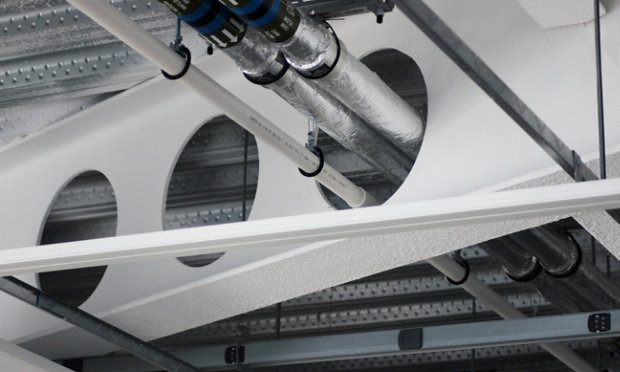

EV Battery Construction and Intumescent Coatings

Duration - 2:6

With the construction of EV battery facilities globally, owners and constructors are tasked with building them faster than ever. Traditional field-applied fire protection installation can cause delays and added project costs compared to shop-applied intumescent fire protection coatings. Sherwin-Williams Firetex® shop-applied coatings can help reduce site congestion, accelerate construction schedules, while improving both safety and quality. Therefore, resulting in reduction of job site insurance costs, field-applied coating disruptions and waste.

FIRETEX® Passive Fire Protection

High Performance Flooring Solutions for EV Battery Manufacturing Facilities

Beyond fire protection, discover a range of industry-leading coatings for EV battery manufacturing facilities, including time and budget-saving solutions for flooring and steel protection. Ask about our consultative, no-charge support services to help guide proper coating specification for these complex operations.

Learn MoreReady To Connect?

Our sales and tech teams are prepared to answer questions regarding which of solutions will best suit your EV battery project— it is never too early to discuss!

Additional Resources

A Wealth of Knowledge

See how we help customers find customised solutions for their project and application challenges.