SofTop™ Provides Comfort Flooring Solution with Sustainability at New Beckhoff Office Building

This new IT facility in Kolding, Denmark used the SofTop™ polyurethane flooring system to provide an extremely tough yet soft finish to be comfortable for office footfall

Selected for its ease of application and performance properties, the specialist resin flooring contractor installed this extremely hard-wearing and hygienic slip-resistant polyurethane flooring solution from Sherwin-Williams.

Situation

Automation Technology expert Beckhoff required a modern seamless floor finish for its new building in Kolding, which would reflect its position as a state of the art automation solution supplier to diverse industries worldwide. Beckhoff established in 1980 now employ 5000 people worldwide and this new facility needed an office floor surface finish to withstand industrial use and to also provide good aesthetics and safety for staff and visitors. The whole area of 550m2 was installed with the Sherwin-Williams SofTop™ SLR Flex system. Specialists from Sherwin-Williams worked directly with the company to ensure that the requirement for a comfort floor type finish, which would be tough with sound absorbing characteristics and have a soft touch. SofTop creates a finish which is very durable and hard yet soft and comfortable for company footfall.

Solution

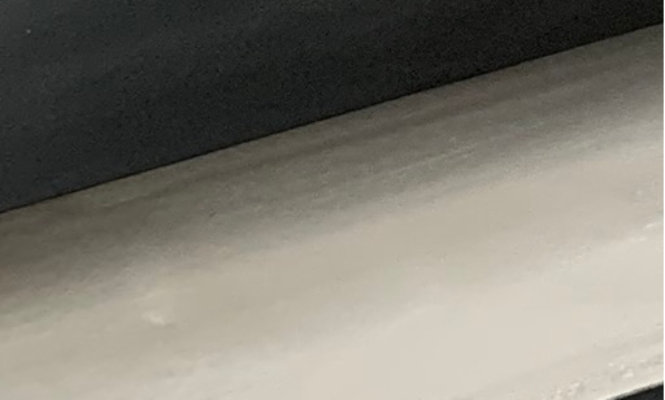

The solution for Beckhoff involved several SofTop products from the Sherwin-Williams range of industrial floor coatings. Following preparation of the concrete base, the specification called for SofTop LVP pure polyurethane resin primer to be roller applied at 300 gr/sqm followed by SofTop™ SLR Flex polyurethane coating applied by squeegee at 3 kg/sqm. For the 'marble type' decorative finish different colours of SofTop SLR Flex are applied at the same time and worked together with a squeegee as a contemporary spatulated finish. This is a contracting application technique using contrasting colours promoted in Denmark as the ‘New Yorker’ design surface. In this instance three shades of Grey were used - RAL 7030, RAL 7038 and RAL 7039. SofTop SLR Flex when applied functions as a self-levelling product which follows the profile of the substrate to which its applied to give a super smooth seamless finish, which would not be possible with a roller applied product. The system was finished with 2 coats of Elladur MC, which is applied as a clear UV stable polyaspartic sealer, which enhances ease of cleaning and wear protection.

Designed primarily with footfall in mind, the SofTop finish is so tough it's suitable for industrial, commercial, and domestic facilities, providing sound-absorbing ergonomics, improving the acoustic properties, and reducing noise impact on other building areas. As well as being more comfortable for footfall, these systems absorb hard shocks, which minimise the risk of back issues for people using the floors.

The formulations for the comfort flooring systems use the latest resin technology and are free of solvents. They include natural plant oils, contributing to environmental standards across Europe demanding low VOC content and good air quality. In line with other resin flooring products, these systems are free of joints and seams, which can hide dirt, bacteria and be flexible. For this reason, the products prevent the formation of cracks from vibration and heavy-duty wear. This is one of the areas where the latest resin technology is used to expand seamless flooring solutions in-line with green building requirements.

Outcome

The company received a SofTop™ floor providing extreme durability and robustness, yet retaining a soft and comfortable finish which is modern and attractive for diverse industrial and commercial applications. The SofTop™ SLR Flex used at Beckhoff is typically installed at around 3 mm thickness providing high wear resistance, high chemical resistance, good sound absorbing properties, and medium resistance to shocks, meeting the company’s requirements.

Sustainability with SofTop

Environmental Product Declarations (EPD’s) are available with the SofTop range which state how the products contribute to Green building designs. Independent EPD verification by NSF provides a recognized method to objectively compare products in the same functional category by their true impact on the environment. Buyers, architects, specifiers and end users can use verified EPDs to assess the ecological impact of the full lifecycle of a product from raw material extraction to disposal. Manufacturers use this process to reduce energy consumption, gauge the position of their products in the marketplace and show transparency in their environmental claims.

This full quantification process begins at the raw material production and extraction phase, then covers the manufacturing process, progressing into packaging, distribution, retail, use and disposal phases. The input and output data, termed as life cycle inventory, is used to create mathematical models for analysis of the products impact. These impacts are then quantified in the LCA and interpreted on a three-tier scale, namely, local, regional and global. These impacts could include climate change (carbon footprint), ecological footprint, water footprint, human toxicity, energy footprint and land fill use.

LCA assessments can be stated in a number of forms, which are presented as variants of LCA. The most common variants of assessment are:

- Cradle to grave-a full life cycle assessment that includes all the stages of a life cycle.

- Cradle to gate-an LCA that deals only with the raw material extraction, production, manufacturing, packaging and transportation processes. It assesses only the activities that occur within the factory. It will not include the distribution, consumer use and disposal phases.

- Cradle to cradle-typically a cradle to grave assessment, where the end-of-life stage of a product is a recycling process, thereby the product will not be discarded after the end of life.

Sherwin-Williams high performance flooring use full "cradle-to-grave" assessments for its EPD creation. This is the only way to provide a total holistic approach representing the entire process, from raw material extraction, application and ongoing maintenance to end-of-life.

Discover More

Industry Expertise and Innovation

See how we help customers find customised solutions for their project and application challenges.

Resin Flooring Resources

Explore system documentation, webinars, and answers to application challenges.

LEARN MOREProduct Lookup

Find out more about our innovative coatings for a variety of industries.

FIND A SYSTEM