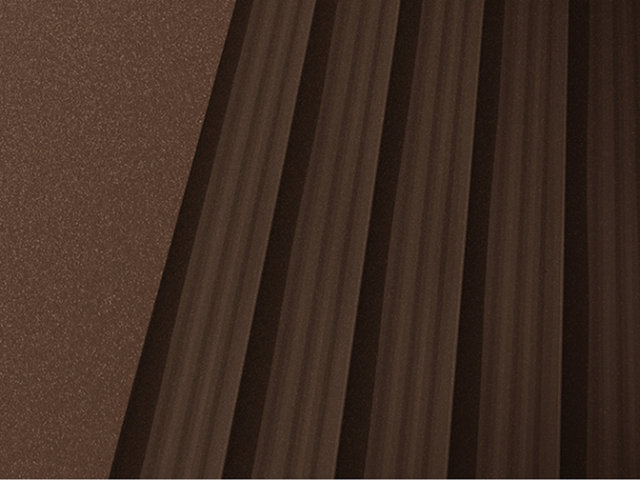

SLATE GRAY

Non-SR: .13

SR: .38

TE: .87

SRI: 41

Can Color Change the Future?

At Sherwin-Williams Coil Coatings, we believe through innovation and a dedication to our customers’ sustainability goals, we can maintain a more vibrant world for generations to come. Together, we’ll explore how color can change the future.

Our Commitment (US Site)

Sustainability is a core value at Sherwin-Williams. We look forward to providing you with solutions that help reduce environmental impacts while staying committed to providing the most vibrant colors.

Product Innovation

Our coatings are designed to do more than enhance an aesthetic; they are formulated to extend and sustain the longevity of metal, so your vision can shine for years to come.

Driving Sustainability Through Innovation

Creating stunning looking products is just the beginning of what we do. Our coatings are designed to resist corrosion, weather harsh elements and showcase beautiful performance for decades.

Sustainability by Design

Innovation and continuous improvement are the cornerstones of our Sustainability by Design program. This program embeds life cycle thinking into the earliest stages of our processes to help us continue expanding our portfolio of products with sustainability attributes.

We’ve defined five sustainability attributes that guide us in product innovation and development:

Our Sustainability Strategy

Our dedication to innovation drives us to improve the sustainability attributes of our existing and upcoming products. We’ve introduced bio-renewables and incorporated recycled materials in our products, lowered VOCs, decreased energy consumption, and reduced waste.

Environmental regulations and performance expectations are continually evolving. We don’t just comply with regulations; we sit on council boards and serve on committees to help drive sustainability conversations, stay ahead of any changes and introduce coating solutions that make compliance as effortless as possible.

Solar Reflective Coatings

We’ve mastered the science of Solar Reflective coatings (also known as Cool Coatings) and offer the highest Solar Reflective coatings values in the industry. These coatings reflect the sun’s rays to offset the urban heat island effect and save energy, effectively lowering heating and cooling bills by up to 40%*.

Paired with the durability of metal, our Solar Reflective coatings enhance the sustainability of any project or residential home. Metal roofs and walls coated with a Solar Reflective coating are an option that offers better energy efficiency, durability, performance and beauty compared to alternative options—all without sacrificing the features our customers desire and expect.

Explore our Solar Reflective products on our English Website: Fluropon®, Illumipon®, WeatherXLTM & WeatherXLTM Crinkle Finish

Customer Partnership

Customer partnership is a priority for us. We’ll work with you to find the right solutions that will support your sustainability goals.

Earning LEED Credits

Our coatings can help you earn LEED® (Leadership in Energy and Environmental Design) credits. From design to construction and operations to maintenance, every aspect of a building's life cycle is analyzed to the most up-to-date environmental standards. Metal components painted with Sherwin-Williams Coil Coatings Solar Reflective and/or Fluropon FP coatings for roofing and wall panels can contribute to achieving LEED points.

Sherwin-Williams will provide our customers with resources, data and solutions to contribute to your project and product goals for LEEDv5:

MATERIALS AND RESOURCES (MR):

- Building Product Disclosure and Optimization – Material Ingredients – Option 1 Material Ingredient Reporting

- Building Product Disclosure and Optimization – Environmental Product Declarations – Option 1 Environmental Product Declaration (EPD)

- Building Life Cycle Impact Reduction – Option 4 Whole Building Life Cycle Assessment

SUSTAINABLE SITES (SS):

- Urban Heat Island Reduction - roof and wall

Each project and product is unique and formula specific. Please work with our Sherwin-Williams representatives to provide you with the information you need.

Focused on the Future

We’re proud to be a part of the global efforts across Sherwin-Williams in protecting our world for generations to come. Learn more about our 2030 sustainability goals in our Corporate Sustainability Report.

Our Commitment to Progress

Sustainability isn’t new to us—it’s embedded in our values, culture and way of doing business. We take an integrated approach to the stakeholders we serve, seeking to meet the needs of our customers, create and maximize value for our shareholders and advance the well-being of communities

Our efforts toward building a better future are guided by these pillars:

- Product Blueprint

- Environmental Footprint

- Social Imprint

Environmental Footprint

Our continuous improvement approach aims to reduce our carbon emissions, energy use and waste generation on top of expanding our renewable energy use and recycling methods.

In doing our part for the planet, we’re working toward achieving the following goals by 2030:

- Reduce absolute Scope 1 and 2 greenhouse gas emissions by 30%

- Increase electricity from renewable sources to 50% of total electricity usage

- Increase operational energy efficiency by 20%

- Reduce waste disposal intensity by 25%

Social Imprint

We are committed to advancing a culture of excellence that values people, inclusion and community. Our commitment is reflected in our unwavering efforts to promote the safety, health and well-being of our people; foster a culture of belonging where individual differences are celebrated; and support those in the communities where we live and work.

Our people are what make us. To attract the best talent out there and help sustain a workforce where our employees can grow, we’re working to:

- Reduce recordable case rate to 0.8 by 2025

- Reduce ergonomic injuries by implementing two ergonomic interventions per year in each manufacturing site

- Attract underrepresented groups into talent pipeline

- Ensure underrepresented groups have opportunities to take on and succeed in leadership roles

- Drive employee engagement

- Foster economic inclusion for underrepresented suppliers

Product Blueprint

Driving sustainability through the innovation of our products is where we make the biggest impact in building a more sustainable future. From life cycle assessments to using bio-renewable materials in our products, we’re implementing sustainability into the stages of our product innovation and development processes.

We evaluate chemical formulations, product performance, manufacturing processes, health and safety considerations and product packaging. Plus, we’ve taken our innovation a step further and integrated Sustainability by Design into our existing Stage-Gate process.

To continue providing world-class products in a safe and responsible manner, we’ve:

- Established the Sustainability by Design Stage-Gate Process as a standard part of the product innovation and development process

- Enhanced the supplier engagement component of our Product Blueprint strategy

- Enhanced our culture of internal engagement to further embed sustainability into the business and into our products

Governance & Ethics

We believe a strong foundation helps us hold ourselves to the highest standards of ethics, business integrity and corporate governance.

Our approach to sustainability performance is managed within a governance structure that enables broad engagement across the organization, while providing appropriate oversight and accountability throughout the Company.

RadGuard™

Sherwin-Williams has a proven history in radiation cure technology. RadGuardTM is a global product line that incorporates Ultraviolet (UV) and Electron Beam (EB) radiation cure technologies.

What is RadGuard?

A new innovation in the coil coatings industry, radiation curing technology changes the way a coating is cured. Traditionally, the coating is cured with a thermal oven while radiation curing uses energy instead of heat to solidify the liquid coating. Used primarily in printing applications, this technology utilizes either Ultraviolet (UV energy) or Electron Beam (EB) to form a coating.

Electron Beam (EB) Radiation Curing

Electron beam curing utilizes accelerated electrons to directly cause the cross-linking of inks and coatings. This allows for a high degree of conversion from oligomer to polymer to take place.

Ultraviolet (UV) Radiation Curing

Ultraviolet Radiation curing works by utilizing high-intensity ultraviolet energy to instantaneously cure the coating. A chemical photoinitiator is used to absorb the UV energy and cross-link the polymers.

Why Choose RadGuard?

Sherwin-Williams, a global industry leader in innovation, offers radiation cure technologies that provide a variety of benefits including:

- Reduction in Floor Space due to dramatically smaller footprint based upon speed of cure and less equipment

- Lower Capital Cost by eliminating expenses associated with multi-stage oven, thermo-oxidizer and other equipment

- No Additional Permitting since radiation cure technology is 100% solids, meaning no need for emission permits

- Sustainability benefits are an important aspect to radiation curing

- Energy Savings through utilization of radiation cure technology that can be more efficient than traditional thermal cure coatings

Driving Sustainability through an Innovative Curing Process

RadGuard is a urethane resin system that boasts long-lasting performance. It can be used in a broad range of applications including gutters, fascia and more. Radiation cure technologies are rapidly advancing in terms of coating performance and equipment capabilities. We are on the forefront of this technology. Sustainability benefits of radiation curing include:

- Lower fire or explosion hazard

- Formulated with 100% solids

- Produces no VOCs (solvent-free)

- Can be retrofitted to an existing line

Harnessing the power of Radiation Curing

RadGuard is available in formulations to align with their application method. The formulations offer similar performance to conventional polyester technologies (durability, color retention, film integrity). However, these products offer greatly reduced capital investment, while consuming less energy, which ultimately benefits your bottom line.

- RadGuardTM EB/UV Clearcoat - applied to protect an existing thermal topcoat.

- RadGuardTM UV Primer - replaces existing thermally cured solvent primer.

- RadGuardTM EB Color Topcoat - applied as a colored topcoat to replace an existing thermal topcoat.

Cool Coatings for Roof & Wall Panels

Sherwin-Williams has brought Solar Reflective (SR) coatings (also known as cool coatings) to the forefront of commercial building design. Cool roof and wall coatings reflect the heat emitted by the sun back into the atmosphere, contributing to lowered energy bills and reducied the urban heat island effect.

Cool Coatings Sell Sheet (English)

Understanding Cool Coatings

“Coolness” is measured by two properties, solar reflectance and thermal emittance. Both properties are measured from 0 to 1 and the higher value, the “cooler” the roof. Solar Reflectance Index (SRI) calculates these two values (solar reflectance and thermal emittance) to determine the roof and wall’s ability to reject solar heat.

- Solar Reflectance (SR): The ability to reflect a percentage of solar radiation from the surface back into the atmosphere.

- Thermal Emittance (TE): The ability to radiate a percentage of absorbed solar energy (heat) back into the atmosphere.

- Solar Reflectance Index (SRI): A calculation method using solar reflectance and thermal emittance values to determine the roof’s ability to reject solar heat.

Visit our English sites to learn more about cool coatings:

Standard vs Solar Reflective (SR) Pigmentation values

Lighter surfaces are cooler than darker surfaces. Solar reflective pigments can help darker colors keep a surface cooler. The table below illustrates how Sherwin-Williams reflective roof coatings keep the Solar Reflectance (SR) and Thermal Emittance (TE) at increased levels when compared to the non-SR coating.

BONE WHITE

Non-SR: .67

SR: .71

TE: .87

SRI: 87

ALMOND

Non-SR: .47

SR: .63

TE: .86

SRI: 75

HAWAIIAN BLUE

Non-SR: .21

SR: .31

TE: .86

SRI: 31

RUSTIC RED

Non-SR: .25

SR: .37

TE: .86

SRI: 39

COPPER PENNY

Non-SR: .20

SR: .46

TE: .85

SRI: 51

The SRI is used to determine compliance with LEED’s heat island reduction credit. When used in new construction, visit our English Site: Sherwin-Williams energy efficient roof systems offer opportunities to earn LEED points for your products. We’ll will work with you to provide the technical information you need to support your program.

Solar Reflective Coatings Help Keep It Cool

Sherwin-Williams offers roof reflective coatings with pigments altered physically and chemically to reflect infrared radiation while absorbing the same amount of visible light. The result is that both the coating and the metal roof stay cooler.

-

Fluropon®

A 70% PVDF resin-based coating with brilliant color that’s made to last.

Fluropon Datasheet (English)

-

Illumipon®

This eye-catching FEVE coating helps monumental structures pop without compromising durability.

Illumipon Datasheet (English) -

WeatherXL™

An SMP resin-based two-coat system that can endure nature’s toughest conditions.

WeatherXL Datasheet (English)

Benefits of Sherwin-Williams Solar Reflective Coatings

Cool roofs and walls are energy efficient, meaning money back on your bottom line. These coatings are engineered to lower energy costs without sacrificing durability, performance and beauty as our customers have come to expect. Additional benefits of SR coatings include:

Exceptional resistance to sun, rain and other natural elements

Resistance to marring, chalking and fading

UV protection

Great flexibility and formability

Superior weatherability

Outstanding color consistency

Proven durability

Energy efficiency

Sustainability Benefits of Cool Coatings

Cool roofing and wall panel requirements appear in national and local energy codes, sustainable building initiatives, and energy rebate programs. Higher SRI Values contribute to lower surface temperatures, reducing ambient air temperatures, thereby mitigating the urban heat island effect. Urban heat islands are caused by roof and pavement surfaces retaining the sun's heat, causing elevated temperatures, increased greenhouse gas (GHG) emissions, and local climate disruptions. Cool coatings minimize these adverse effects, while increasing occupant comfort and reducing the occurrence of health issues associated with poor air quality and smog. When used in new construction, cool coatings systems offer opportunities to earn LEED credits such as:

- Building product disclosure and optimization - material ingredients

- Building product disclosure and optimization - environmental product declarations

- Building life cycle impact reduction

- The heat island reduction – roof and wall

When you design with sustainability in mind, it is crucial to use products and suppliers that offer you the resources and solutions to help you meet your goals. At Sherwin-Williams Coil Coatings, we work directly with our customers to help their projects achieve standards of national and global initiatives.

Applications and Use Cases for Solar Reflective Coatings

Cool coatings can be applied to a number of pre-treated substrates, including Galvalume® aluminum, and Hot-Dipped Galvanized (HDG) steel and can be applied to the following building products:

Metal roofing

Metal wall panels

Aluminum extrusions

Architectural curtain walls, louvers & grills

Architectural windows, skylights, doors and access systems

Case Studies in English

Case Studies

Visit our United States Website to review some projects that feature our Cool Metal Roofing