Cutting Costs with Water Storage Tank Restoration Overcoating

Holyoke Saves Over Half the Cost Restoring Five Large-Capacity Municipal Water Storage Tanks

The Challenge: High Water Storage Tank Restoration Costs and Tight Municipal Budgets

Saving any sort of money on maintenance projects is a blessing for municipalities that face consistently tight budgets year after year. But saving over $1.2 million on the rehabilitation of five water storage tanks was like winning the lottery for the City of Holyoke, Massachusetts.

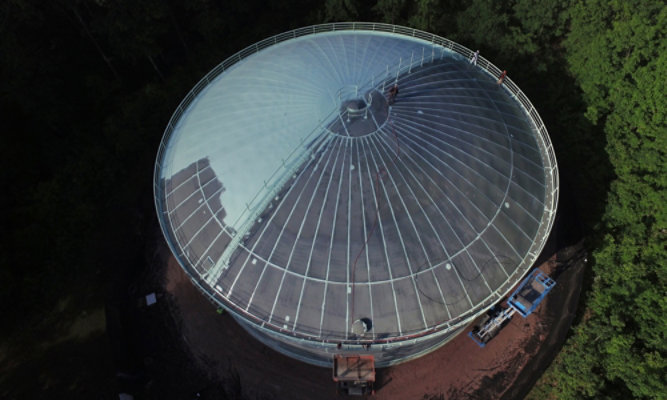

In 2020, the Holyoke Water Works was prepared to restore the exteriors of four large-capacity surface water storage tanks with a total capacity of 10 million gallons. The exterior coatings systems on the tanks were dirty, covered in mildew and showing signs of deterioration. Based on visual assessments, it was initially assumed full restoration was required for all four tanks. That would mean setting up full containment systems for each tank, dry blasting their exteriors and then applying a three-coat protective system on each to combat corrosion and enhance aesthetics. The original cost estimate for the coatings work totaled $2.2 million, which the city was prepared to spend.

All told, the original budget and plan for the work was sound for a project of this magnitude. However, the city received a welcome surprise when the total price tag for the job dropped by more than half, thanks to an astute assessment of the tanks’ conditions that confirmed they could be restored using a two-coat overcoat system instead. This revelation removed the need for setting up full containment and dry blasting the tanks to bare metal. Given the major cost savings, Holyoke Water Works decided to add a fifth tank to the bid – one that definitely required a full restoration. Despite adding that tank to the overall project, the total price for completing the coatings work dropped by $1.2 million – to just $980,000 – saving over half the original estimated cost.

The Solution: A Water Storage Tank Overcoating System That Extends Service Life and Reduces Costs

The project team discovered the large savings potential after a closer look at the condition of each tank. During the specification stage of the project, representatives from Sherwin-Williams Protective & Marine and Westfield, Massachusetts-based engineering services firm Tighe & Bond assessed the mold and mildew growth on the tanks and looked for areas of damage or peeling paint. Washing away some grime with a 5,000-psi pressure washer in accordance with the SSPC SP-WJ4 Waterjet Cleaning of Metals – Light Cleaning method revealed a mostly intact coating surface with minimal signs of corrosion. Next, the assessment team performed SSPC SP-6 Commercial Blast Cleaning on select areas to determine how well the undercoat was adhered. Because the existing coatings were still tightly adhered on four of the five tanks, the team and owner settled on overcoating those tanks and using a coating system designed for application to marginally prepared surfaces. The fifth tank would need to be blasted down to bare steel and receive a full three-coat system.

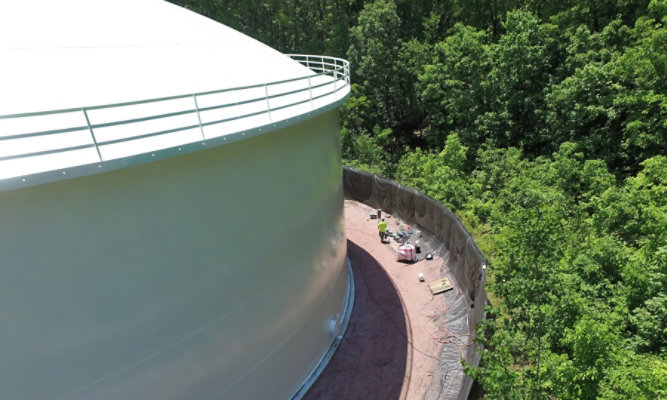

Kicking off the restoration of each tank, applicators from Champion Painting Specialty Services Corp. performed the same initial pressure washing step on the entirety of the tanks to fully assess their conditions. Applicators then performed SSPC SP-6 (WAB) Commercial Wet Blast Cleaning on any areas of spot corrosion and feathered the edges of remaining coatings to provide a good tie-in for the overcoat layers.

For the overcoat system, applicators first spot primed any areas that were blasted to bare metal using Macropoxy® 646. Next, applicators applied a full coat of Macropoxy 920 Pre-Prime on the entire tank. Finally, applicators applied a topcoat of Sher-Loxane® 800, which combines the hard barrier protection of an epoxy with the flexibility and UV stability of a polyurethane.

Compared to the four tanks above, the two-million gallon tank that required the full restoration had visible rust spots bleeding through the coating. Applicators opted to prepare the tank’s surface using vapor blasting. This method, combined with the tank’s remote location, allowed the team to forgo the time and expense of erecting a full containment system. The team vapor blasted the entire tank to the SSPC SP-6 (WAB) Commercial Wet Blast Cleaning standard for a clean, contaminant-free surface. Next, applicators applied Zinc Clad® 4100, an organic, polyamide epoxy, zinc-rich coating for corrosion protection. Applicators used Macropoxy 646 as the intermediate coat and applied a topcoat of Sher-Loxane 800.

The Results: Major Savings on Water Storage Tank Restorations Enable the City of Holyoke to Fund More Infrastructure Projects

Completing the five tank restorations in July 2021 with four overcoats and only one complete rehabilitation, the City of Holyoke realized major savings compared to the high initial price tag for taking all of the tanks down to bare steel. This large budget savings enabled the city to address additional time-sensitive infrastructure projects that otherwise may have been delayed or remained unfunded.

Our Water & Wastewater Expertise

Explore our industry solutions and technology to help protect your assets.

LEARN MOREProduct Lookup

Find out more about our innovative coatings for a variety of industries.

FIND A PRODUCT