Offshore Coatings

Protective coatings for offshore atmospheric and subsea

WHAT are Offshore Coatings?

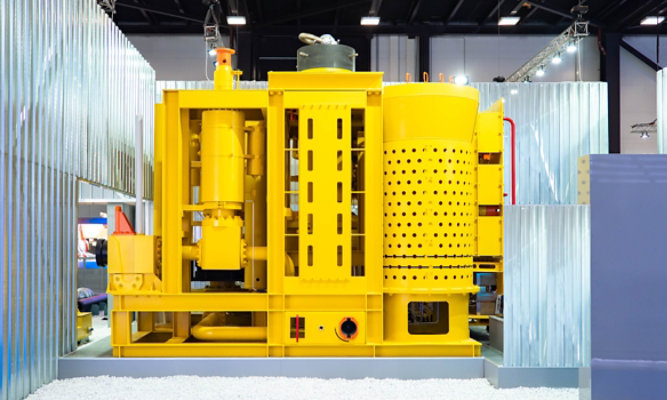

Offshore oil and gas operations involve the extraction of petroleum and natural gas from beneath the ocean floor. The rigs, pipelines, and equipment utilized in exploration, drilling, and production are in demanding and corrosive environments. Risk of fire is also a grave concern for personnel and assets. Protective coatings are used to improve the overall safety and efficiencies of operations by mitigating deterioration caused by corrosion, abrasions, fire, and environmental wear.

Sherwin-Williams high-performance solutions deliver long-term protection, rapid curing, and ease of applications to help owners protect offshore assets from the fabrication shop to the sea — whether offshore atmospheric or subsea. Our solutions feature complete coverage and excellent edge retention, and outstanding durability, abrasion, and chemical resistance to minimize corrosion damage.

- Protects against corrosion

- Protects against chemical degradation

- Reduces out-of-service time for critical assets

- Protects against corrosion under insulation

- Protects corrosion under fireproofing

- Protects concrete, steel, and ductile iron

Anti-Corrosive Coatings for Offshore Above & Subsea

Offshore environments, whether above the waterline or subsea, present distinct challenges that necessitate specialized protective coatings. Equipment above the waterline must be shielded from severe weather conditions and the corrosive effects of the splash zone, where waves frequently impact. Subsea equipment and piping require protection against elevated temperatures, high salinity levels and corrosion from the transported materials.

Sherwin-Williams protective coatings offer:

- Superior corrosion and chemical resistance for above, subsea and fabric maintenance

- Increased speed of installation due to ability to pre-welded and coat piping onshore

- Trusted performance through pre-qualification to global industry standards reducing costs with maintenance and shutdowns

Long-Lasting Offshore Coatings

Our offshore coatings are exceptionally robust, designed to endure the rigorous demands of the offshore environment. The application process is streamlined, minimizing downtime while delivering enduring asset advantages. Sherwin-Williams epoxy, polyaspartic, and polyurethane coating systems adhere seamlessly to steel surfaces, providing comprehensive protection against chemical exposure, impacts, abrasions, and corrosion.

With their outstanding protective qualities, our coatings are engineered for longevity. Utilizing our coating solutions, you can significantly extend the operational lifespan of oil rigs, floating facilities, pipelines, drilling wells, and other assets, thereby enhancing performance and reducing long-term maintenance expenses.

Explore some of our recommended products below and contact us to discover which solutions are best suited for your specific needs.

Recommended Products

Ready To Connect?

Our sales and tech teams are prepared to answer questions regarding which of our coating systems for offshore will best suit your project— it is never too early to discuss!

Lunch & Learns

Asset Protection for the Energy Sector

Enhance your knowledge of protective coatings and linings within the energy sector. We offer engaging Lunch and Learn sessions designed to guide your organization in selecting the most suitable systems for your specific applications.

-

In-person Presentations

- 5 Presentations to choose from

- Custom presentations available

- Developed by industry leaders

- Earn PDH Credits

Additional Resources

A Wealth of Knowledge

See how we help customers find customized solutions for their project and application challenges.

Explore MoreEnergy Resources

Explore our knowledge base on all things coatings and linings for Energy.

Learn MoreEnergy Newsletter

Subscribe to our Fueling the Future newsletter for essential energy insights.

Subscribe Today