Bellmont Cabinet Company

Coatings supplier change to Sherwin-Williams eliminates finishing issues and improves product quality.

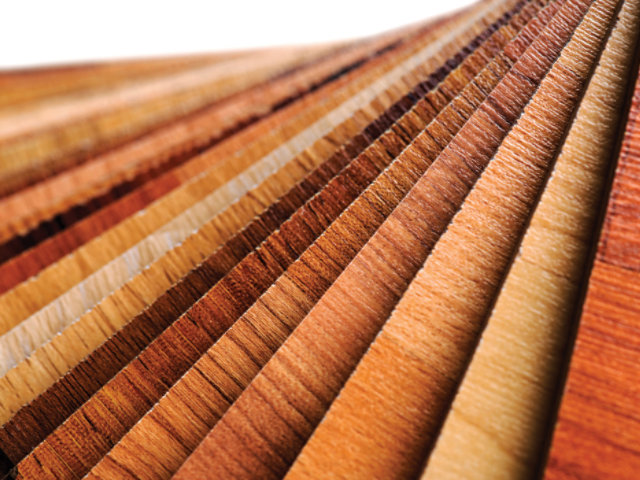

As a manufacturer of custom and semi-custom kitchen cabinets for the building and remodeling markets, Bellmont Cabinet Company relies on its supplier partnerships to maintain superior product production and quality. For the Sumner, Washington company, one area of acute importance is finishing.

“Finishing is the hardest thing that any wood manufacturer does,” said Chief Operating Officer Casey Bell, son of company founder and President Steve Bell. “You have to understand that problems can arise, and what makes or breaks a manufacturer is the support that a coatings company provides.”

The family-owned business provides frameless, Euro-style cabinetry that delivers style, quality and value to its customers – a nationwide network of dealer partners, with a strong customer base in Washington, California and Hawaii. Bellmont’s primary sales focus is the remodeling market, but the company also sells to remodelers through Lowe’s under the “Latitude” brand name.

A shift in suppliers yields quick results

In 2004, Bellmont introduced a line of painted cabinets, offering three different colors – white, biscuit and alabaster. Its coatings supplier recommended a non-catalyzed primer coated with a catalyzed pigmented topcoat. Failures in the field – cracking and peeling finishes – were a fast indication that something was wrong.

“It got to the point where we were replacing products for too many jobs,” recalled Bellmont’s Finish Materials Manager Kevin King. “The supplier said that it wasn’t their fault. They claimed that we must be over-catalyzing the second coat or just not coating properly. But we had strict parameters in place.”

When issues began to appear on the clear coat varnish used over both painted and stained products, the company invited Sherwin-Williams to offer a solution to its finishing woes.

“Sherwin-Williams offered us a unisystem approach for the painted cabinets – we learned that you can’t put a catalyzed topcoat over a non-catalyzed primer,” said King. “With the products Sherwin-Williams offered, we put on the first coat and let it dry. We sanded it and then put on the second coat, and we were done. We put some test doors in a room with full sunlight to see if the coating would yellow, crack or peel. After a month, there were no problems. It’s a process to change vendors, but within six weeks we were up and running full bore with Sherwin-Williams.”

Sherwin-Williams achieved a clear coat solution through the application of a non-yellowing cellulose acetate butyrate (CAB) catalyzed conversion varnish. The clear coat provides topcoat protection on Bellmont’s painted and stained cabinets. It provides added protection from scratching during installation and over the service life of the cabinets, King noted. Similar in nature to an automotive urethane topcoat, the CAB conversion varnish “just offers a better level of overall protection.”

Switching coatings suppliers provided the added benefi t of faster delivery, too. Sherwin-Williams guaranteed delivery within three days for all standard products – a significant improvement, King noted, from the weekly deliveries offered by the previous coatings supplier.

Today, deliveries are arranged on an every-other-day schedule from a Sherwin-Williams facility located less than 30 miles away.

“We’re a lean manufacturer,” said King. “We don’t have huge warehouses full of material. We have just enough of everything to last for a few days. The biggest finishing competitor is located in another state. They can’t do a three-day-per week delivery for us. And if I really need something, I can call and Sherwin-Williams will have it here by 10 a.m. the next day.”

Process improvements impact product quality

A staff of 50 makes up Bellmont’s finishing department, working two shifts, fi ve days a week. Eight spray booths are used for staining and painting. An additional spray booth provides special finishes, such as glazing. All finished products are clear coated on two Cefla flat line sprayers.

King says that the Sherwin-Williams partnership continues to pay dividends in terms of process improvements. The companies partnered to improve drying times on the flat line finishing systems to speed production. Most recently, the companies worked together to improve throughput and reduce waste by introducing two on-demand catalyzing pumps to apply the pigmented conversion varnish coatings. The plural component equalizer system automatically injects catalyst into the paint as it is being sprayed. The system also allows for quick color changeovers.

“There’s less waste because we can make small, custom batches by catalyzing only what we need on demand,” he said. “It eliminates the potential for human error because you can’t use too much or too little catalyst, and that reduces scrap. The spray guns we bought along with the catalyzing pumps create a superior fi nish to what we had before.”

Casey Bell added that color consistency is key to meeting strict quality standards. It is important that dealers involved in remodeling projects can be confident that a finish is consistent from project to project. New customers must be able to expect a fi nish that matches what they may have seen in a remodeling dealer’s showroom.

“We knew we wanted to achieve a higher level of consistency with our finishes and devoted a lot of research and development to develop a process that has helped us achieve it,” Bell said. “Sherwin-Williams was at every single one of those meetings to help us. They have done a great job of being involved with other vendors. When we have techs in from other suppliers to work on our flat line finishers or spray equipment, we don’t make any decisions without Sherwin-Williams’ guidance.

The two companies also teamed up for a two-day painter training class conducted by hand-spraying experts from Sherwin-Williams. Twenty Bellmont finishing employees participated in the class. The first day of class was primarily classroom work, and the second day was a hands-on shop floor session that helped the finishers understand the proper method of disassembling equipment and cleaning spray guns. They learned spray gun adjustment techniques for paints and stains by reducing air pressure and increasing fl uid pressure to eliminate overspray to reduce waste and the amount of coatings used.

“We have had training like this before, but this was a little different,” King said. “It helped the attendees make decisions from stain to stain, from paint to paint; it even taught them how close to stand to the product they’re spraying. They learned what to do, and what NOT to do.”

We’re a lean manufacturer. We don’t have huge warehouses full of material. We have just enough of everything to last for a few days. The biggest finishing competitor is located in another state. They can’t do a three-day-per week delivery for us. And if I really need something, I can call and Sherwin-Williams will have it here by 10 a.m. the next day.

Place an emphasis on high-performing, sustainable products

Bellmont’s commitment to environmental and social responsibility, or holistic eco-friendly manufacturing, has been in place for over 20 years. The company carries the Environmental Stewardship Program seal of certification administered by the Kitchen Cabinets Manufacturers Association (KCMA).

This commitment holds through not only the sourcing of particle board and hardwoods used to manufacture cabinets but also to waste management, conservation processes and air quality standards in the manufacturing process. Recycling cardboard, wood and sawdust is a big part of the waste management effort, but Bellmont also employs a system that recycles all of the solvents used in the finishing process into reusable, clean solvents. The flat line system used for the clear coat reduces emissions by more than 30 percent. Top coat overspray is captured and reused as a sealer coat.

“Sherwin-Williams has assisted us in this effort by developing products that help us meet our environmental goals,” King said. “They have helped keep us out of being a Title V producer,” added Casey Bell. “Our manufacturing levels are growing, but our hazardous waste reporting is not.”

Measuring success continually

The companies have worked together for over a decade to improve processes, fi nish quality and color consistency. Styles change, and so do fi nishes, which means that the standards for measuring success evolve as well. In the end, it all comes down to support.

“I measure a lot of what happens in finishing in terms of bad things, things that aren’t working,” Casey Bell said. “You need support there, and that’s the value of Sherwin-Williams. When things aren’t going right, they’re here to help us work through the problems right away.”

“The number one benefit is customer service,” King said. “If I have a question that Sherwin-Williams can’t answer, they know who to talk with to get the answer – fast. That’s a huge benefit.”

The Right Products

We delivered a unified coatings approach to fix the non-compatible primer/topcoat issue Bellmont faced. Check out our full line of coatings by industry to learn more about our offering - you just may find the right solution to your biggest challenge.

Learn MoreTechnical Service Support

Through regular technical support, we helped Bellmont improve color consistency and overall finish quality. Our experienced technical service team is at your service throughout the finishing process, so you can be confident that we are with you from start to an exceptional finish.

Learn MoreLocal Service

We were able to offer Bellmont faster delivery, getting them standard products within three days from their local facilities. We know that time is money, and with 76 facilities throughout North America, we're committed to getting you what you need, when you need it.

Find a FacilityMedia Center

More Case Studies

Scroll to see more examples of how we've worked with our customers to solve their toughest challenges.

View All Case StudiesCase Study

May 21, 2024

Castleberry Case Study

Castleberry Shutters Boosts Productivity With SHER-WOOD® EA Hydroplus™ Waterborne Topcoat

Let's Connect

Discover the perfect coating solution for your manufacturing needs and unlock a world of possibilities with Sherwin-Williams. Learn more about how our kitchen cabinet coating systems can provide a boost to your productivity and your bottom line.