The Essentials of Composite Coatings

Physical and chemical composites enhance coating properties to boost performance

by Neil Wilds, Global Product Director – CUI, and Dr. Jeffrey David Rogozinski, Global Product Director – Fusion-Bonded Epoxy/Pipe, for Sherwin-Williams Protective & Marine

Sometimes a little added reinforcement is all that’s needed to turn a well-performing coating into a high-performing composite coating. Such physical composite coatings combine two or more substances that together offer performance properties that are greater than the sum of their parts. The same is true for chemical composite coatings, which also deliver enhanced properties based on chemical reactions that occur as the coatings cure. In either case, the composite coatings may feature enhanced anti-corrosion, chemical resistance, flexibility, abrasion resistance and/or adhesion properties, among others. Without the added substances in physical composites or the reactions that occur in chemical composites, the coatings wouldn’t perform nearly as well.

Applicators can also enable composite-like performance by building up coatings in layers to create coating systems that offer enhanced overall performance compared to their individual, single-layer results. In such cases, each coating layer may or may not be a composite itself.

This article will review the various types of composite coatings and describe how they enable more robust performance by enhancing properties such as corrosion resistance, durability, flexibility and resistance to cathodic disbondment.

What Are Composites?

Coatings can become composites in one of two ways, depending on whether they’re formed physically or chemically.

Physical composite coatings are very straightforward. Manufacturers start with a traditional liquid coating and enhance it by adding substances like glass flake, micaceous iron oxide (MIO), ceramics or other materials. When mixed in, these additives distribute homogenously throughout the coating film to provide additional properties. For example, glass flake can help to add toughness, reflect ultraviolet (UV) radiation (to delay UV degradation) and/or add compressive or tensile strength. Physical composites begin as homogenous mixtures and take final form during the curing process. As solvents or activators are released from the coating solution, the constituents of the coating shift and align physically throughout the coating to provide even coverage and protection within the film. This alignment is evident in Figure 1, which shows how MIO flakes cured within a coating’s matrix align to deflect UV rays and mitigate the penetration of moisture, oxygen and other electrolytes into the coating.

Chemical composites, which can be made within fusion-bonded epoxies (FBEs), are considerably more complex. They take the initial form of powders, which are essentially inert until they’re activated by the application process. For example, when powdered FBEs are sprayed onto the pre-heated surface of a steel pipe, the powder will quickly turn to a liquid that flows together and bonds chemically during this process due to molecular-level changes within the material. The components of the coating “phase-separate,” with fast-reacting, contiguous phase molecules rapidly forming a latticework of crosslinks that give the coating a particular degree of toughness, temperature tolerance (based on the glass transition temperature (Tg) of the coating) and barrier properties, along with flexibility.

During the application of powdered FBEs, the contiguous phases of the coating react so quickly that the crosslinks they form surround and envelope other moities, resulting in “occlusions” throughout the crosslinked structure. The distribution of these “occluded phase” molecular structures are key to the coating’s flexibility and toughness. Singly and collectively, the molecules within these occlusions function as pillows or shock absorbers within the rigid crosslinked structure, absorbing and dissipating impact and flexing forces across the coating surface. The occlusions help to prevent forces from concentrating in a single place where an impact – such as rocks being dropped on top of a pipeline during installation (Figure 2) – could crack or break the harder lattice of crosslinks. The occlusions also enable incredible flexibility for the coatings, allowing offshore oil and gas exploration operations to install pipelines using the reel-lay method, which involves reeling kilometer-long sections of pipeline onto spools onshore for efficient installations offshore.

Considering the Layers

One coating, even a composite, doesn’t necessarily give you every needed property, especially in challenging applications. Therefore, a third way to create a composite-like coating is to layer various materials to create a multi-layered coating system. This practice occurs naturally any time applicators use more than one coating layer, primers included, as each layer offers its particular protective benefits to the coated asset for greater collective asset protection as the layers stack up. Any multi-layer coating system can offer added protection simply by creating a greater physical barrier between exterior elements and the coated asset’s substrate. Yet, these systems can be even more robust when some or all of the various layers that make up the coating system are composites themselves. Ideally the complete system will offer a covalently-bonded, multi-level protective barrier with performance properties that work synergistically as a unified, multi-layered composite structure.

Take coatings that are used in up to three layers (Figure 3), for example, to protect the exteriors of buried pipelines. For virtually every application involving a steel pipe – from subsea to underground to above ground – anti-corrosion coating properties are paramount. Therefore, the bottom-most layer of a pipeline coating system is optimized for this task with a combination of exceptional adhesion and long-term anti-corrosion properties. This FBE coating layer, which is a chemical composite itself, is characterized by high flexibility and a high, but balanced degree of adhesive and cohesive properties. The balance of these properties is important to resisting cathodic disbondment and – in the event of physical damage (e.g., impact damage or scratches) to the coating – to preventing or greatly limiting any surface corrosion from spreading by undercutting the anti-corrosive coating. The fine-tuned properties of this composite FBE layer prevent corrosive elements from reaching the steel pipe substrate with outstanding resistance to cracking, cold flow and softening over a wide temperature range.

Pipeline applications can benefit greatly from an additional layer of protection – applied on top of the base anti-corrosion layer – that’s designed to resist physical and chemical attacks. This even tougher, more flexible chemical composite FBE coat provides a high level of abrasion resistance to help prevent any scratches and scrapes a pipe may encounter from transportation to installation from cutting through this layer. For example, testing to the NACE TM0215-2015 standard showed that applying significant pressure to the coating resulted in compressing the coating but not gouging it (Figure 4). Without this protective layer, the anti-corrosion layer could be damaged, exposing the bare steel below and increasing corrosion potential. This additional composite layer also provides a moisture barrier to mitigate the potential of water penetrating through to reach the anti-corrosion coating.

Finally, in some applications, those responsible for pipeline installations may want to consider a third layer of composite-like protection – one designed to preserve the lower layers against UV degradation. This optional layer may be warranted for aboveground pipelines, as well as underground or subsea projects in which substantial delays exist between coating pipes and installing them. Due to their epoxy formulation, FBEs don’t age well under UV light. Because many pipes must be transported long distances while exposed, they’re subject to a great deal of detrimental UV exposure. This is also true for pipes that may sit for long periods at the pipeline installation site before being installed. The longer the exposure, the greater the risk of the protective and corrosion prevention FBE coating layers deteriorating and reducing their performance. Adding an outer protective coating layer of a fusion-bonded polyester or water-based acrylic coating prevents UV light from reaching the FBEs, prolonging their lives.

Resisting Cathodic Disbondment

Physical, chemical and multi-layer composite coatings provide a variety of added properties that help the coatings perform better and longer in their intended applications. Among those properties, enhanced resistance to cathodic disbondment is a key benefit for pipeline operators using composite FBEs to protect buried or underwater pipes from corrosion.

Such pipeline installations commonly use cathodic protection (CP) systems as a backup corrosion mitigation system. CP systems apply a current to a pipeline that allows electrons to flow from a sacrificial anode to a steel surface to prevent corrosion. FBEs are designed to work synergistically with CP systems to provide a two-pronged approach to corrosion prevention. The FBEs applied to the pipeline provide barrier properties that protect the metal pipe substrate from corrosion, with the CP system serving as the backup.

If a break forms in an FBE coating in a pipeline installation supported by a CP system, the resulting electron flow allows the sacrificial anode to corrode preferentially to the pipe. Within the area of the coating break, alkalinity increases due to the CP current’s interaction with water and electrolytes. That higher alkaline concentration adversely affects the coating adhesion and can therefore make it prone to cathodic disbondment. However, that cathodic disbondment can be mitigated by using chemical composite FBEs with strong adhesion potential that have been lab- and field-tested to confirm their performance. Such FBEs should also be non-shielding, meaning they allow the current from the CP system to reach the steel pipe substrate and therefore enable cathodic protection. If the FBEs shielded the pipe from that current, the CP system would not provide much backup corrosion protection if any.

A Composite Future

Through continuous research and development, it has become possible to develop composite coatings that can perform various tasks synergistically. The coatings themselves may include physical additives that enhance their adhesion, strength, durability, thermal performance and resistance to abrasion, moisture penetration, chemical attacks and corrosion. Alternatively, the coatings may form those enhanced properties chemically as various elements within their formulations cure and bond together to form an interlocking coating matrix. In addition, different coating layers can be built up and bonded together into a unified, multi-layered composite structure that offers specialized types of protection. In any of these cases, the composite coatings offer enhanced properties compared to non-composite coatings. Such properties can be especially beneficial to the long-term anti-corrosion performance of the coatings.

ABOUT THE AUTHORS

Neil Wilds is Global Product Director – CUI for Sherwin-Williams Protective & Marine. With 36 years of technical coatings experience, Wilds develops strategies for long-term asset protection and directs the development of specifications and testing programs. He is a member of several coatings associations including AMPP, NORSOK M501, the International Organization for Standardization (ISO) and others. Contact: Neil.Wilds@sherwin.com

Dr. Jeffrey David Rogozinski is Global Product Director – Fusion-Bonded Epoxy/Pipe for Sherwin-Williams Protective & Marine. With more than 30 years’ experience in coatings and academia, he is responsible for developing protective coatings, powder coatings, resins and additives for the oil and gas, pipeline, and bridge and highway markets. His coatings science emphasis is on researching and testing polymer synthesis and structure-property characterization. He is a member of several coatings associations and a consultant for global specification writing for CSA Group, the International Organization for Standardization (ISO), ASTM International, AMPP and others. Rogozinski holds a doctorate in applied science for polymer and composite chemistry. Contact: Jeffrey.Rogozinski@sherwin.com

Figure 1. MIO pigments embedded in a coating form a barrier that deflects UV rays to minimize degradation of the coating. The layered pigment structure also mitigates the penetration of moisture, oxygen and other elements into the coating.

Figure 2. Rock drop testing (top) proved that a chemical composite fusion-bonded epoxy (FBE) overcoat provides the impact and abrasion resistance required to protect the base anti-corrosive FBE layer from becoming exposed (bottom).

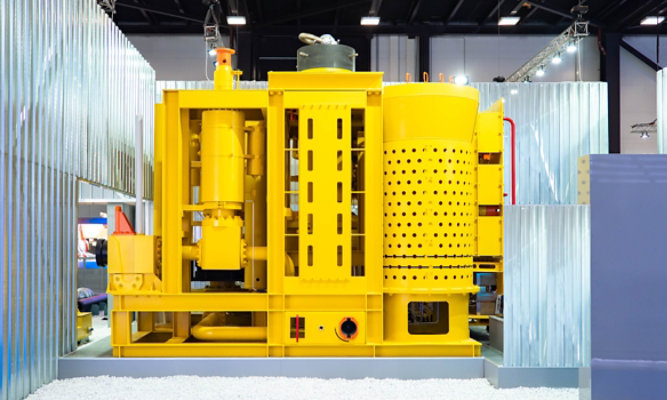

Figure 3. A multi-layered approach to coating pipelines for long-term performance includes:

|

Figure 4. Performing the NACE TM0215-2015 test, technicians applied an ASTM-specified R33 drill bit to an abrasion- and moisture-resistant FBE overcoat to attempt to gouge it. Applying 32 kg of pressure (top) barely affected the coating. With 62 kg of applied pressure (bottom), the coating compressed at the drill bit interface but did not gouge.

Discover More

Industry Expertise and Innovation

See how we help customers find customized solutions for their project and application challenges.

Our Oil & Gas Expertise

Explore our industry solutions and technology to help protect your assets.

LEARN MOREProduct Lookup

Find out more about our innovative coatings for a variety of industries.

FIND A PRODUCT