Woodmont Cabinetry

Woodmont Cabinetry looks to Sherwin-Williams to be its “all-in” solutions provider

Through steadfast relationships with customers and suppliers, Woodmont Cabinetry, based in Dallas, Texas, continues to expand its cabinetry operation after 66 years in business. For more than 10 years, Sherwin-Williams has been the company’s sole coatings supplier, fulfilling Woodmont’s requirement to be an “all-in” partner.

SELECTIVE FOR GOOD REASON

Woodmont Cabinetry, a division of Western Cabinets, Inc., was purchased by the Tidwell family in 1992. The company started as a small regional manufacturer, supplying products to North Texas home builders, but has grown into having more than 400 employees, serving home builders throughout the United States.

By creating strategic partnerships with large-scale customers, Woodmont has differentiated itself from other cabinetry manufacturers. The company doesn’t seek mass retail, nor does it pursue multiple distributors in the same city.

“We are exclusive and selective when it comes to vetting customers, mainly because we see them as partners,” said Stanley Tidwell, President of Woodmont Cabinetry. “We take care of them by supplying high-quality products complete and on time. They take care of us by protecting our brand integrity.”

Woodmont isn’t just particular about its customer relationships – it’s selective about its supplier relationships too. Around 2009, in the thick of the recession, Woodmont began to investigate new coating suppliers that could provide durable finishes and pledge to be “all-in.”

Sherwin-Williams could deliver on both promises. “Great opportunities surface during times of disruption,” said Tidwell. “Our Sherwin-Williams rep helped rebuild our infrastructure. We turned our focus back to quality finishes. We came out of the recession with stronger, better products than when we went into it.”

Great opportunities surface during times of disruption. Our Sherwin-Williams rep helped rebuild our infrastructure. We turned our focus back to quality finishes. We came out of the recession with stronger, better products than when we went into it.

PREPARATION & PRODUCT

With years of collaboration and commitment under their belts, the companies have perfected the finishing process at Woodmont.

“Woodmont uses multiple product lines from Sherwin-Williams but mainly SHER-WOOD® Kemvar® and Sayerlack® Hydroplus™,” said Wes Goodman, Sherwin- Williams Sales Representative. “They’re excited about the new Sayerlack Pigmented Hydroplus product. It’s going to save them a lot in operational costs.”

Tidwell says Sayerlack Hydroplus Pigmented Topcoat is going to revolutionize one of Woodmont’s factories. The product eliminates the need for a thermal oxidizer, which is expensive to install and operate. According to Tidwell, much of Woodmont’s success is contingent on the pre-finishing process.

To ensure top-notch quality and consistency, the skilled crafters at Woodmont sand all components multiple times throughout the finishing operation by machine and by hand. For application, Woodmont relies on the line of Sames Kremlin spray equipment offered through the Sherwin-Williams Associated Products program.

DESIGN INFLUENCE

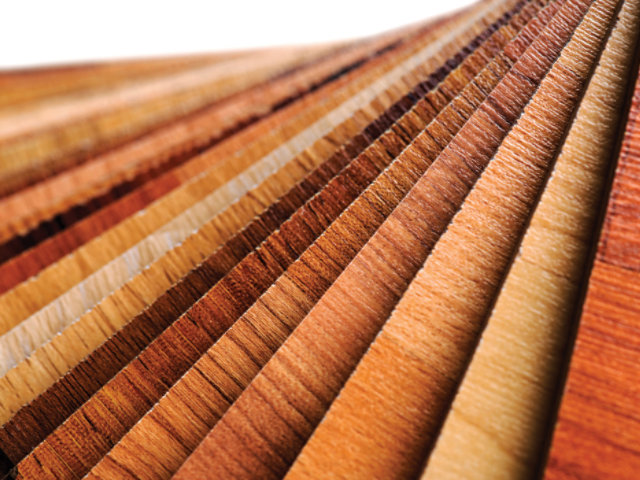

Anticipating consumer design trends has become increasingly significant for Woodmont’s product development process. Like many manufacturers of home building products, the company has tightened its focus on style, color and shape to meet both builder and end-user expectations.

“Influences like home design shows, social media and online inspiration platforms make interior design more accessible,” said Jaime Tidwell Foster, Corporate Director of Human Resources and Marketing for Woodmont Cabinetry. “We’ve seen a big shift in the market as far as customization goes. Homeowners don’t want that cookie cutter look. They want style and color options.”

At least once per year, Woodmont visits the Sherwin-Williams Global Color & Design Center (GCDC), a facility in Greensboro, North Carolina dedicated to forecasting wood color and design trends. The cabinetry manufacturer works with the color experts at the GCDC to analyze home and color trends, adding another layer of collaboration among the two companies.

“Sherwin-Williams has the unique ability to understand how important it is to build relationships at every level,” said Stanley Tidwell. “Their people have integrity, and they’re committed to finding solutions that propel our business.”

The Right Products

To improve finishing line efficiencies and save operational costs, Woodmont Cabinetry relies on our proven product solutions. Check out our full product lineup. You may just find the right solution to your biggest finishing challenges.

Learn More

Color and Design Services

Woodmont Cabinetry works collaboratively with our Global Color & Design Center, meeting with our experts regularly to discuss the latest color and finishing trends. Read more about our color and design services.

Learn More

Equipment and Supplies

For application, Woodmont Cabinetry trusts the line of Sames Kremlin spray equipment offered through our Associated Products program. Learn more about our one complete solution for your finishing operation.

Learn MoreMedia Center

More Case Studies

Scroll to see more examples of how we've worked with our customers to solve their toughest challenges.

View All Case StudiesCase Study

May 21, 2024

Castleberry Case Study

Castleberry Shutters Boosts Productivity With SHER-WOOD® EA Hydroplus™ Waterborne Topcoat

Let's Connect

Discover the perfect coating solution for your manufacturing needs and unlock a world of possibilities with Sherwin-Williams. Learn more about how our kitchen cabinet coating systems can provide a boost to your productivity and your bottom line.