Hinkle Chair Company

Hinkle Chair Company collaborates with Sherwin-Williams to protect its 184-year-old legacy with durable finishing solutions.

Few companies today can boast 184 years in business. Hinkle Chair Company has been making indoor and outdoor hardwood furniture since 1834. As two

organizations that have surpassed a cumulative 335 years in business, Hinkle and Sherwin-Williams aim to create durable, best-in-class products for their customers. For more than 20 years, Hinkle has relied on Sherwin-Williams to deliver finishing solutions.

FROM TOBACCO BARN TO FINISHING FACILITY

Hinkle Chair Company is a family-owned and operated business, headquartered in Springfield, Tennessee. In the mid-1800s, the Hinkle family began making ladder back chairs to supplement their income as farmers. By 1932, the family made the decision to become full-time chair manufacturers, utilizing an old tobacco barn as a factory. Shortly after this decision, Hinkle introduced rocking chairs to its product line.

In the 1980s, Hinkle Chair expanded its furniture collection to include new chair designs, tables, hutches and buffets. To accommodate rapid growth, Hinkle extended its footprint and production capabilities by building new facilities, including one dedicated to finishing.

“At first, we tried numerous paint and finish manufacturers,” said Jeff Hinkle, Vice President of Hinkle Chair. “By the late 90s, we went 100% Sherwin-Williams because they could provide the durable solutions we demanded while working within our price range. We told our sales reps what we needed, and they delivered. It’s been the same solid relationship ever since.”

Our Sherwin-Williams tech representative has been extremely helpful. He ensures cross-hatch testing is done properly, and he checks to see if our adhesion, millage, color and consistency standards are all met – resulting in cost savings for us.

STAIN AND COLOR SOLUTIONS

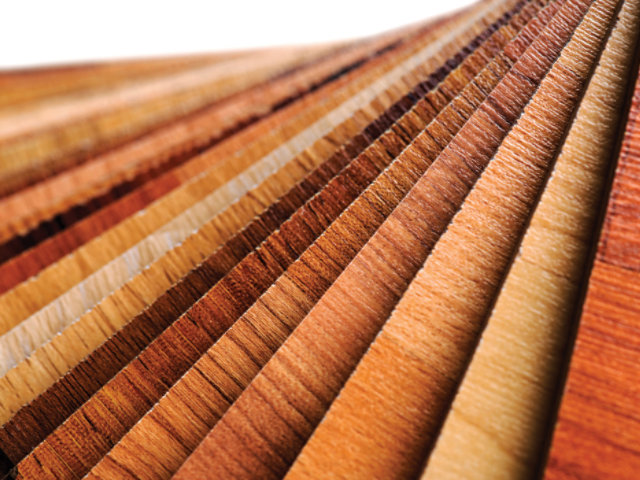

Hinkle mainly utilizes the SHER-WOOD® line of stains, engineered to accent and highlight grain definition in wood products. SHER-WOOD formulas, including conversion varnishes, sealers, basecoats, glazes and wiping stains, are applied to Hinkle’s chairs, benches, swings and other wood furniture. In addition to providing various color stain options, Sherwin-Williams has developed more than 50 custom vinyl basecoat colors for Hinkle’s collegiate and military rocking chair collections. To achieve specific colors, such as Tennessee Orange and North Carolina Blue, the operations manager at the Sherwin-Williams commercial facility in Nashville, Pam Arms, works closely with Hinkle on color development.

“Paying attention to color and finishing trends is important to us,” said Diane Hinkle Johnson, Marketing Director at Hinkle Chair. “We’re working on new colors, and we’re also trying out new deck stains that will hold up longer in outdoor environments.”

SERVICING THE GLOBAL VALUE CHAIN

The majority of Hinkle’s products are designed and developed in Springfield, but volume production now occurs in China. Transitioning the bulk of the company’s manufacturing to China was no easy feat. “Hinkle has put a lot of effort into perfecting its processes overseas, including finish applications,” said Jeff Lewis, Sherwin- Williams sales representative. “All products are prepped, stained and sprayed in China.”

A full-time Sherwin-Williams technical service representative oversees the finishing process at the China facility to ensure quality and consistency requirements are met. When products arrive to the states, Hinkle conducts a comprehensive inspection.

CLAIM TO FAME

Rocking chairs are Hinkle’s top-performing product, selling up to 75,000 per year. The chairs can be seen lining the porches of Cracker Barrel Old Country Stores nationwide, serving as a symbol of community and relaxation. The retail portion of Cracker Barrel sells Hinkle’s classic, collegiate and military-themed rocking chairs– all finished with coatings from Sherwin- Williams – citing the chairs as one of the most popular items sold in its stores.

“It’s great to be able to say our products are coated with Sherwin-Williams because the brand name carries weight,” said Jeff Hinkle. “As far as service goes, I could go on and on about our positive relationship with Sherwin. It’s just been total cooperation.”

The Right Product Solutions

Hinkle utilizes the SHER-WOOD line of stains, including conversion varnishes, sealers, basecoats, glazes and wiping stains to accent and highlight grain definition in its wood products. Check out our full product lineup. You may just find the right solution to your biggest finishing challenges.

Learn More

Technical Support

Hinkle relies on their Sherwin-Williams technical service representative to ensure their operation is running efficiently, resulting in cost savings. Our technical team is with you throughout the finishing process, so you can be confident that support will be there from start to a beautiful finish.

Learn More

Global Service

Hinkle relies on Sherwin-Williams' global connectivity to ensure manufacturing continuity in Asia. Whether or not your business is multinational, you'll benefit from our global technology transfer, product availability, inventory management, product consistency and expertise across your value chain.

Learn MoreMedia Center

More Case Studies

Scroll to see more examples of how we've worked with our customers to solve their toughest challenges.

View All Case StudiesCase Study

May 21, 2024

Castleberry Case Study

Castleberry Shutters Boosts Productivity With SHER-WOOD® EA Hydroplus™ Waterborne Topcoat

Let's Connect

Discover the perfect coating solution for your manufacturing needs and unlock a world of possibilities with Sherwin-Williams. Learn more about how our kitchen cabinet coating systems can provide a boost to your productivity and your bottom line.