Easy. Fast. Simple.

The FIRETEX® Application Process

FIRETEX® isn’t just designed to provide up to 2 hours' protection during a cellulosic fire. It saves time and money too. Our products, such as the FX6000 series, are designed around the common challenges faced by contractors, applicators and steel fabricators, with the aim of supporting a quick and easy application, inspection and handover process.

Whether you're looking to reduce delays in the application process or achieve a high-quality finish on-site using standard single-leg spray equipment, we have a FIRETEX® coating to suit your needs.

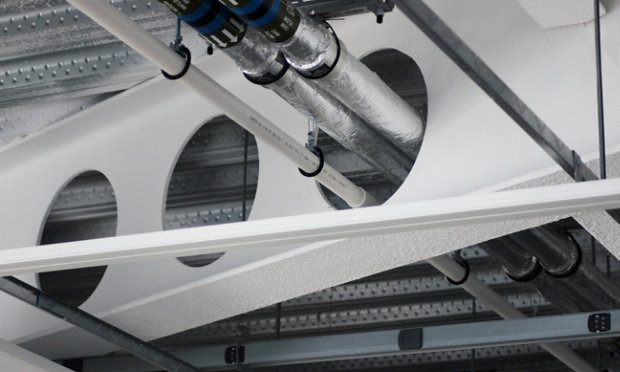

Flexible application methods

On-site or off-site application - it's entirely up to you. FIRETEX® coatings are designed for rapid, easy application for a maximised throughput, with strong mechanical properties providing damage resistance during transportation and erection on site, for shop-applied steel.

Learn more about the modular construction process:

Read article

Rapid Drying Times

Time is money, and when you’re up against a tight construction schedule, you need to reduce delays and ensure a fast application process. With drying times as low as 1 hour for FIRETEX® FX6002, our intumescent coatings can transform your in-shop application throughput or offer optimised on-site productivity with reduced overcoating, inspection and hand-over times.

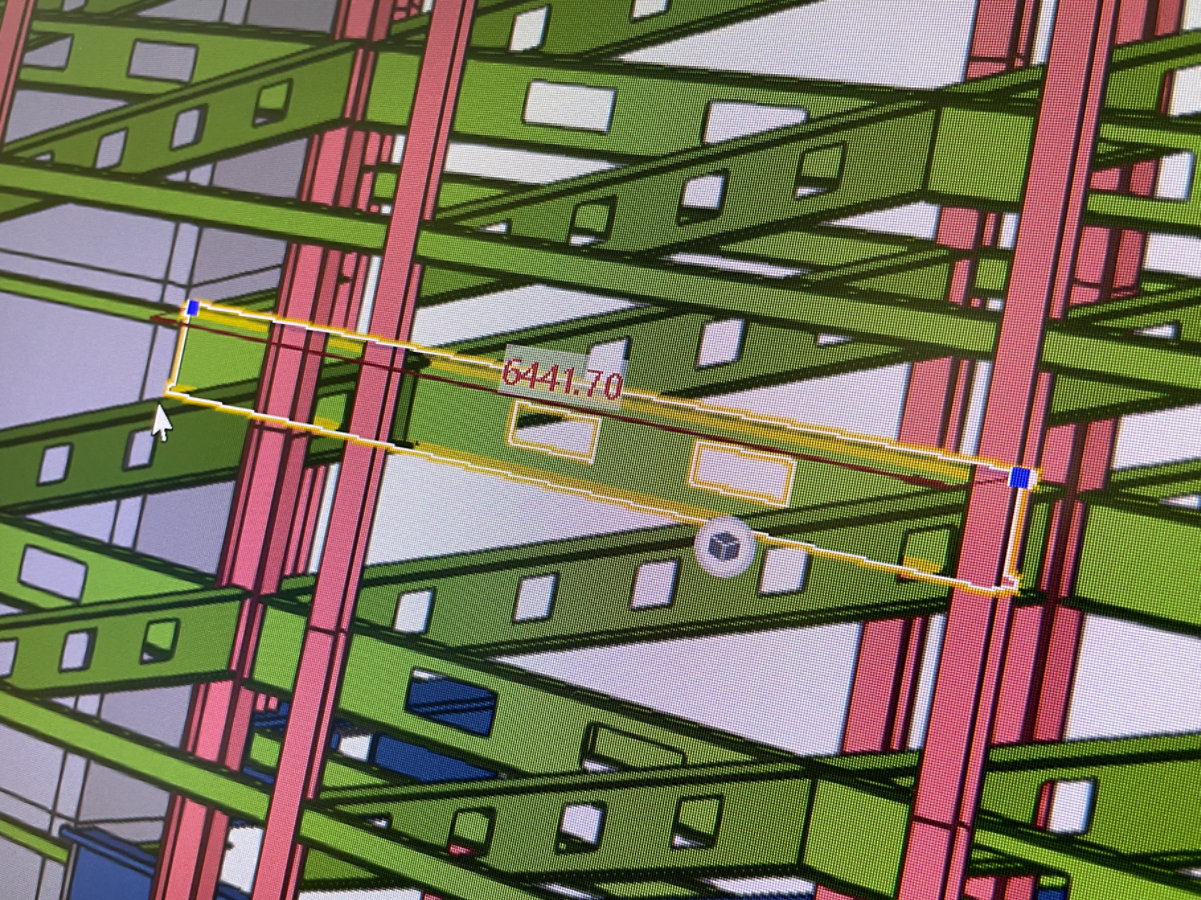

Improve the efficiency of your application process with FEET

Our Fire Engineering and Estimating Team (FEET) can support your application process, offering dry film thickness (DFT) and carbon equivalent (CO2e) estimations using our third-party certificated FIRETEX® Design Estimator (FDE) software.

Find out how FEET can help you take the guesswork out of your intumescent coating application activities:

Discover FEET

Intumescent coating technical support

Our Technical Services Department is always on hand to deliver product and equipment demonstrations, best practice recommendations and customised training packages supported by our veteran industry subject matter experts. Our specialists are also able to provide on-site assistance to help you achieve the best possible results.

Find out how our technical specialists keep your support needs covered

Technical serviceFIRETEX® Passive Fire Protection

Discover More

Industry Expertise and Innovation

Explore customised solutions we deliver for customers to address their project and application challenges.